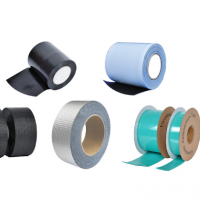

underwater adhesive tape

T700 PE underwater adhesive selant tape for corrosion protection of Oil, Gas, Petrochemical, Waste

Water underground/overhead/underwater pipelines and waterproofing.

The specification of the tape consists of three layers,

Adhesive: Butyl rubber(BR).

Film backing: Special blend of stabilized polyolefines.

Interleaf: Anti-adhesive Film Treated with Silicone.

Technical Data Sheet:

|

Physical Properties |

Test Method |

T700-15 |

T700-20 |

T700-40 |

T700-50 |

T700-65 |

|

|

Total Thickness |

ASTM D 1000 |

1.15mm |

1.20mm |

1.40mm |

1.50mm |

1.65mm |

|

|

Backing Thickness |

ASTM D 1000 |

0.25mm |

0.25mm |

0.35mm |

0.45mm |

0.50mm |

|

|

Adhesive Thickness |

ASTM D 1000 |

0.90mm |

0.95mm |

1.05mm |

1.05mm |

1.15mm |

|

|

Tensile Strength |

ASTM D 1000 |

>60 N/cm |

( >34.3 lbs/in ) |

||||

|

Elongation |

ASTM D 1000 |

>300% |

( >300% ) |

||||

|

Peel strength to Primed Steel at |

|

||||||

|

At 23 ºC |

ASTM D 1000 |

>40 N/cm |

|

||||

|

Adhesion to backing |

ASTM D 1000 |

>20 N/cm |

|

||||

|

Cathodic Disbondment |

ASTM G 8 |

8.0mm |

( 0.315 in radius ) |

||||

|

Water Absorption Rate |

ASTM D 570 |

<0.10% |

( <0.10% ) |

||||

|

Water Vapor Transmission Rate |

ASTM F 1249 |

<0.1 g/m2·24h |

( <0.0064g/100sqin/24h ) |

||||

|

Insulation Resistance |

ASTM D 257 |

2.5×1015 ohm.cm |

( 2.5 by 10 E 15 Mohm ) |

||||

|

Dielectric Strength |

ASTM D 149 |

28 KV |

( 28 KV ) |

||||

|

Impact Resistance |

ASTM G 14 |

15 J |

( 133 in·lbs ) |

||||

|

Color |

Black |

||||||

|

Tape width in inches |

50mm(2"),101mm(4"),152mm(6"),228mm(9"),305mm(12"),457mm(18"),610mm(24"),750mm(29.5"),800mm(31.5"),1000mm(39") |

||||||

|

Tape roll length in feet |

15m(50ft),25m(82ft),30m(98ft),50m(164ft),61m(200ft),100m(328ft),122m(400ft) |

||||||

|

Application Temperature |

-34 ºC to +120 ºC |

|

|||||

Main advantages: COULD BE APPLIED UNDERWATER.