JIDA High Glossy Marble PVC Wall Panel

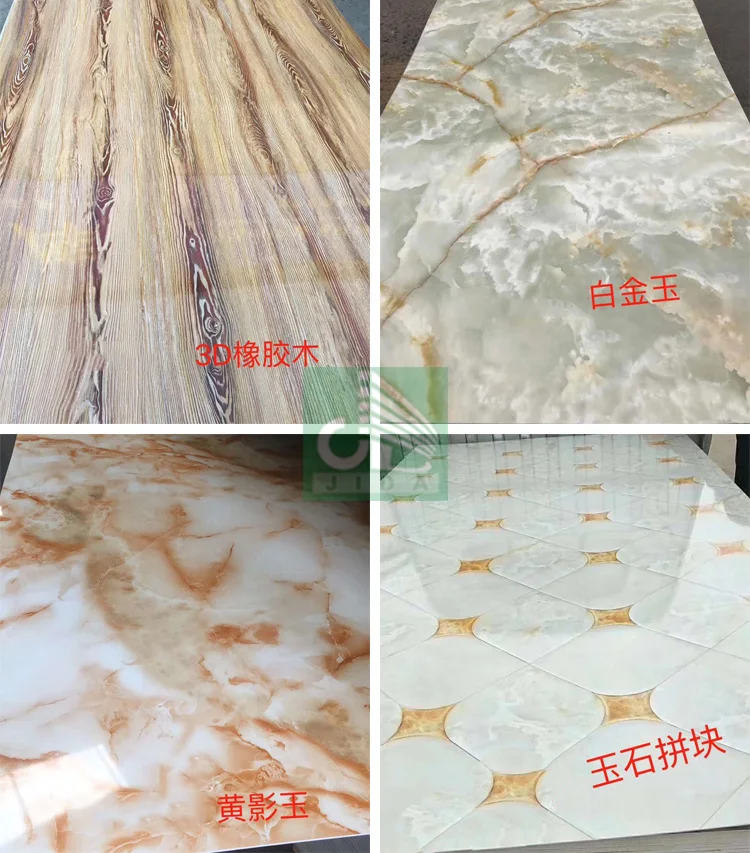

Marble Color UV Coating PVC sheet, also named PVC marble sheet or Mable plastic sheet or high gloss UV Stone plastic board or high glossy PVC UV sheet etc.

Marble Color UV Coating PVC sheet, also named PVC marble sheet or Mable plastic sheet or high gloss UV Stone plastic board or high glossy PVC UV sheet etc.

1. Why there are so many names?

Because this is new product and people give it name according to their understanding to the material composition or panels application or panels features.

2. Why called high gloss UV stone-plastic board?

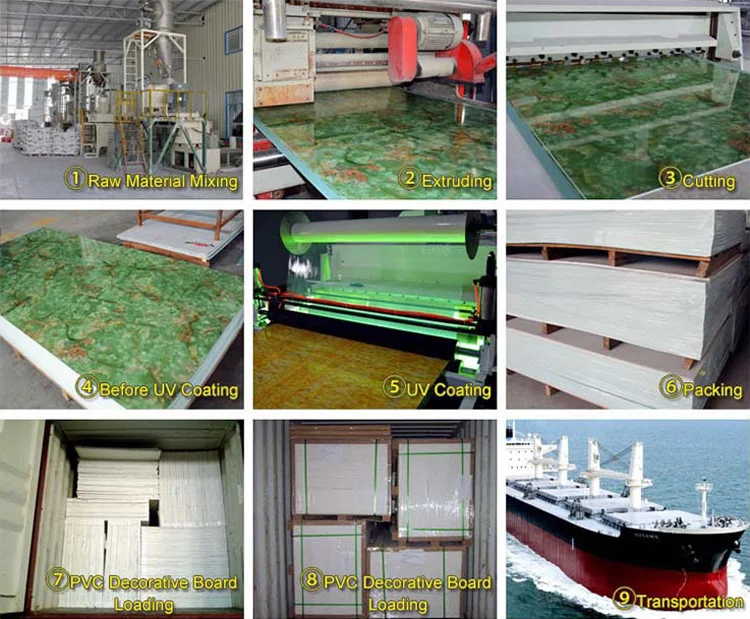

Because the basis board are extruded sheet by extruding machine ,the material is PVC powder (which is one kind of plastic) mix calcium powder (which is from stone) then mix some fortifier. So the main composition is stone and plastic. So call Stone-plastic sheet/ board/ panel.

3. Why called UV board?

The surface of panel will be laminated various designs PVC film or hot stamped various designs so the surface can appear various designs. Then coating UV on the surface then the surface is high glossy and scratch resistant which reach 2H.

4. Why called marble sheet or marble board?

The invention of this product is to instead of natural marble or granite. Compared with natural marble. This product have big advantage for the customers. Their weight is 1/5 of natural marble, their price is 1/10 of natural marble. Without any radioactive substances, don't effect the body healthy and environment. Without any color difference, because the surface is laminated PVC film or hot stamped so without any color difference. So we called high glossy marble sheet.

| Product Name | High Glossy UV Board, UV Wall Panel,Marble texture Board, Marble sheet, Mable Plastic Sheet, Faux Marble Sheet, PVC Marble Sheet, PVC Marble Panel, PVC Marble Board. |

| Brand Name | Our brand name is JIDA and we also can supply OEM. |

| Material | PVC resin and calcuium cartonate. |

| Composition | 30%PVC, 67% CaCo3, 3% Additive. |

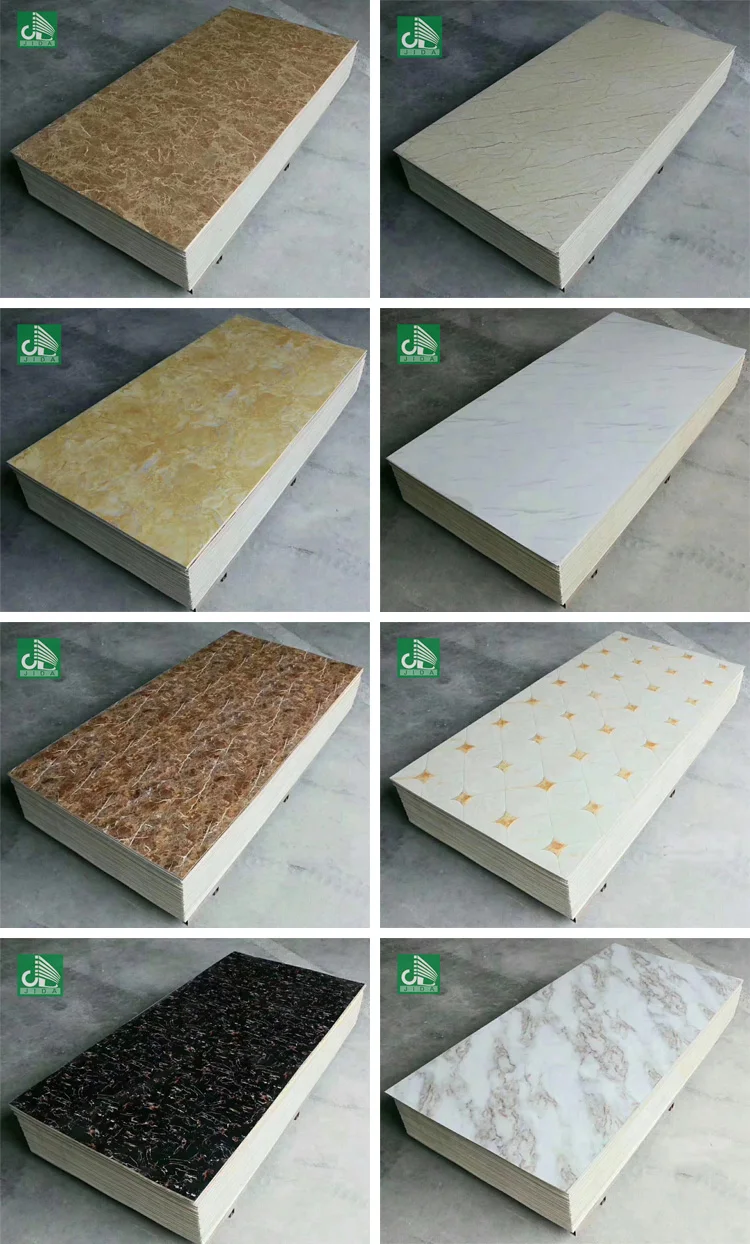

| Structure | PVC rigid board+hot stamping film or PVC film+UV coating+PE protective film. |

| Density | 2.0g/cm3. |

| Regular Specification | Standard size: 1220*2440mm and 1200*2400mm. Other sizes for customization. Standard thickness: 2.8mm and 3.0mm. Available thickness: from 1.0mm-6.0mm |

| Surface Treatment | Hot stamping film or PVC film with UV coating. |

| Usage | For Interior Wall. |

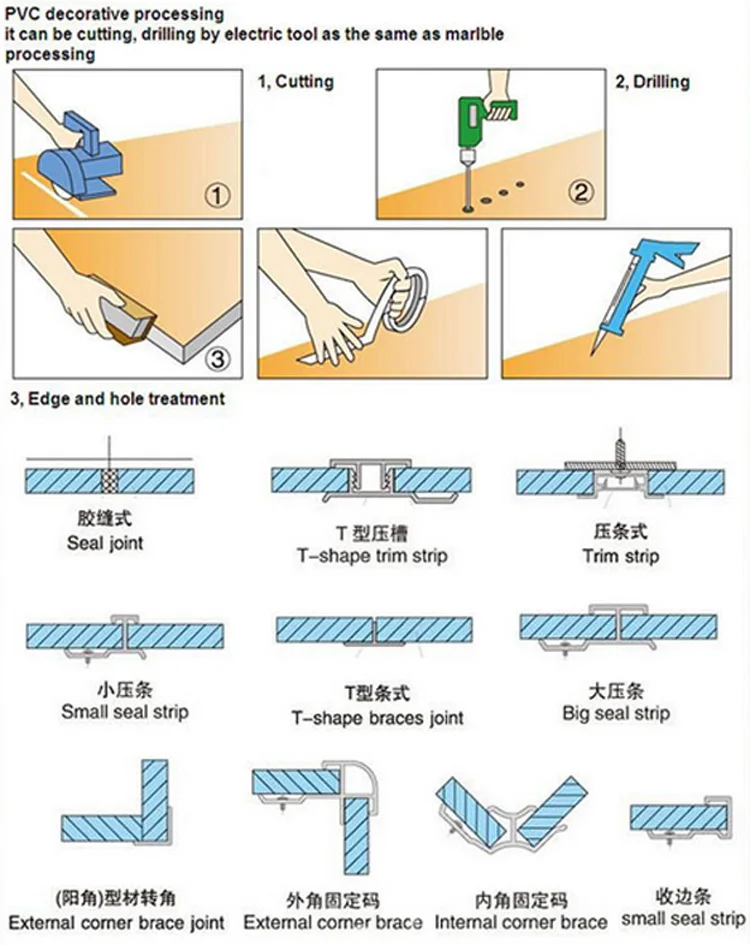

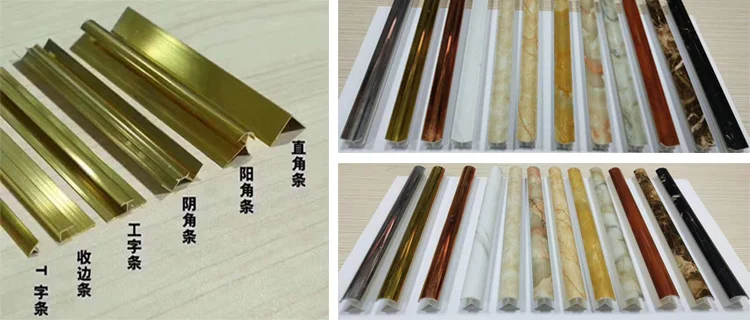

| Installation | Glue on wall. |

| Glue | Silcone adhesive. |

| Feature | Green Environmental Producti: 100% without asbestos, formaldehyde, benzene and other harmful substances. |

| Non flammability: this product is non flammable and conforms to the national B grade. | |

| Water proof and moisture proof: this product is allowed to long term expose to moist environment. | |

| Problem free :don’t promote bacterial growth or transmission,non toxic ,anti-corrosion and chemical resistance | |

| High strangth ,high hardness 2H-4H ,high/low temperature resistance ,high glossy with wear resistant and easy to clean. | |

| The weight is only one fifth of the natural marble and the price is one tenth of the natural marble. | |

| Easy installation, easy cutting, long service life with low maintenance cost . | |

| Application | The ideal subsitite of natural marble, widely used in decoration of interior wall, such as restaurant, hotel, villa, KTV, Suppermarket, bar, cafe, office, kitchen, toilet, hotel, airport, subway station. |