Production

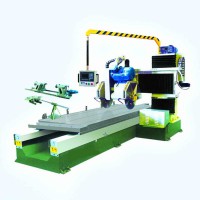

This multi function computer stone copying machine is a high intelligent special shaped stone processing equipment.It mainly process all kinds of shape such as flex,roman column,big arc plate ,arc board ,striped panels. You can add industry installed automatic processing all case column,a sphere and a solid column.The machine’s screen can be directly displayed on the processing program,the whole Chinese prompt,according to the curvature of the automatic selection of running intervals,and can double knife cutting,with a very high efficiency make good product quality.

Main technique parameter

|

Blade diameter |

350-600mm |

Maximum cutting board length |

3000-3800mm |

|

Maximum working depth |

180mm |

Main motor power |

15kw |

|

Horizontal stroke of saw blade |

1500mm |

Water consumption |

4m³/h |

|

Horizontal arm lift stroke |

800mm |

Outline dimension |

5000×2200×2400mm |

Usage of stone the product

The Stone multi function computer copying machine is used to process large arc width flower lines, special-shaped domes and curved surfaces of arbitrary shapes. It can also process cylinders, vases, Roman columns and fences around cemeteries. The machine uses special computer software to input graphics, which saves the trouble of template making compared with infrared copying, and makes the work more precise and efficient.

Stone with special shape can not easily meet the user's requirements if it is handled manually or processed by finishing machines such as stone carving machines. Manual processing is not suitable for large-scale stone processing, which is inefficient and costly. Stone engraving machine belongs to fine processing, the cost of mass use is too high. Therefore, in view of the need for mass production of copying building materials, our factory's multi functional computer copying machine is very suitable.

You can use the stone multi-function computer copying machine to mass produce the following shapes of stone.

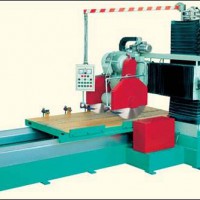

The working principle of stone copying machine

Stone copying machine is divided into two types, one is template type, that is, carving drawings into templates, stuck in the middle of two optical fiber sensors, automatically copying according to the template, making blanks, and then hand-polishing; the other is computer-based, drawing into instruction code, input into the computer, automatically generate control finger. To control the left and right stepping motors, process them into blanks, and then grind them manually.

General operation flow of stone copying machine

1. According to the size and shape of the processed stones, the stones should be placed or fixed reasonably on the workbench.

2. Install and adjust the copying template (you can check whether the location is appropriate);

3. Open the cooling water valve;

4. Start up the motors.

The instructions should be read carefully before the above operations.