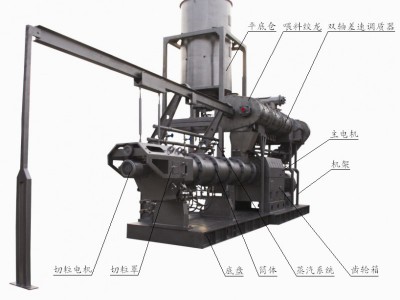

Product Features

1. The gearbox is the fifth-generation product of the company. It adopts the conventional flat double-structure gearbox. After being improved and strengthened, the torque coefficient and service life are greatly improved. The service life is 100,000 hours, and there is no failure for 5 years under normal use. The user checks and maintains the machine every year, and replaces the engine oil and oil seal.

2. The barrel is made of medium carbon steel, the forgings are processed, and the heating layer and cooling layer are integrated forging structure.

3. The inner sleeve and screw of the barrel are made of high wear-resistant alloy steel, which greatly improves the service life. The normal service life of the inner sleeve is 6000 hours, and the normal service life of the screw is 3000 hours. The main motor uses a frequency conversion motor, which can be changed according to the material formula To adjust the screw speed and produce qualified products of different specifications.

4. It can produce uniform pellet feeds of various shapes with floating and sinking diameters between Φ0.5mm-Φ50mm and no powder is produced.

5. The formula of the feed material produced can contain more than 18% oil and fat, and does not affect the puffing effect.

6. The raw materials of the produced feed are more evenly matured and the degree of maturity is higher.

7. Compared with the single-screw extruder with the same power, the output has increased by nearly 30%.

8. Compared with the single-screw extruder, the use of starch in the formulation can be reduced by about 30%.

9. It can produce water-floating, slow sinking and sinking pellet feed.

Scope of application: Widely used in the production of extruded and extruded aquatic feed (floating water material, slow sinking material, fast sinking material), various pet foods, and can be used in the production of plant tissue protein and snack food in the food industry.