During the winding construction of polyethylene cold winding tape, we still need to pay attention to some points. In addition to making sufficient preparations before construction and derusting its steel pipe, we also need to pay attention to some points during construction. Let's have a look.

1、 Handle the objects before use

For example, when we want to use polyethylene cold winding tape to wind the steel pipe, we must first carry out certain treatment on the steel pipe. For example, before use, we must do a good job in rust removal, deburring, degreasing and welding slag removal. For such problems as rust removal, a certain level should be achieved.

2、 Precautions for using primer

For many metal materials, if polyethylene cold winding tape is used for winding, some primer shall be applied first. For the selection of primer, the attention should be paid to the selection of products matching with polyethylene cold winding tape. The attention should also be paid to keeping away from open fire. Before use, the primer should be stirred evenly. After the primer is applied, do not wrap polyethylene cold wrapping tape immediately, but use it after the primer is dry.

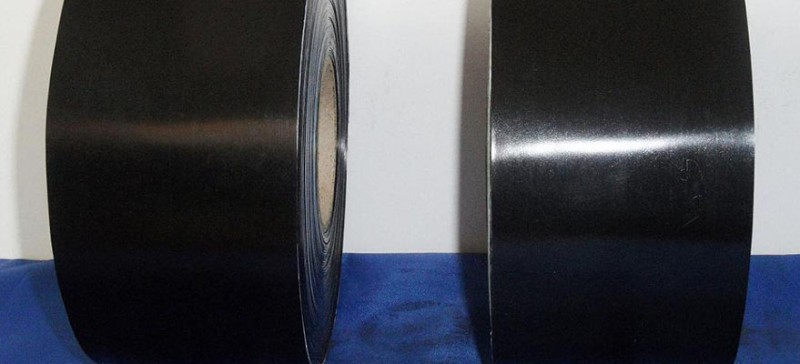

Polyethylene cold winding tape

3、 Underground backfilling

The problem to be noted is that if the products wrapped with polyethylene cold winding tape need to be backfilled underground, they can only be backfilled after passing the acceptance of the quality inspection department.

The above three points need our attention in the construction of polyethylene cold winding tape. In fact, we all know the derusting treatment of the pipeline before use, but we should also use the right methods to make it better cleaned, so as not to affect our construction. For the treatment of the other two primers, we should also follow the correct methods.