QGN series automatic shot blasting machine for steel pipe internal cleaning

- 20 years experienced engineers provide best proposal for your need.

- Customized design available

- Oversea engineer service avaliable

- To aim to save your cost and improve efficiency

- Over 8000 clients from more than 30 countries and regions all over the world

- Biggest producer of shot blasting machine/wheel blasting equipment and abrasives in China.

- Main products: shot blast machine/ shot blasting machine/shot blast cleaning equipment/wheel blasting equipment, such as tumble belt shot blasting machine, hook type shot blasting machine/hooking shot blasting machine/hanger type shot blasting machine, steel belt shot blasting machine, steel wire mesh shot blasting machine/mes belt shot blasting machine, catenary shot blasting machine, piled and released shot blasting machine, turntable shot blasting machine, trolley type shot blasting machine, steel plate shot blasting machine, steel sheet pre-treatment line/shot blasting and painting line, steel pipe shot blasting machine/pipe internal shot blasting machine/pipe outer wall shot blasting machine, haning pass through type shot blasting machine, mechanical hand type shot blasting machine/robot shot blasting machine, sand blasting machine/sand blasting room etc.

QG Series Steel Pipe Wheel Blast Machinery is suitable for the surface treatment of steel pipe and related products, wiping up the oxide coating, welding slag to make the surface appear metallic sheen, increasing the surface area. It is widely applied in the industries, such as petroleum & chemical, steel, city centralized heating, centralized drainage, etc

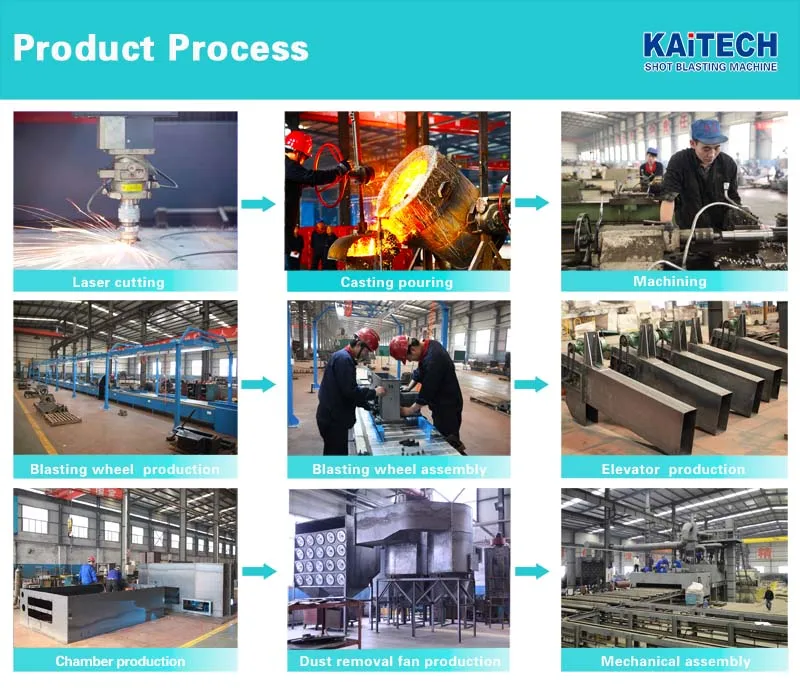

General Description For Shot Blasting Machines:

All Shot Blast Cleaning Machines include these basic design criteria:

1) Blast Wheel(s) - The wheel(s) propels or throw(s) the abrasive media.

2) Work Handling system - depending on the design type of machine this may be rubber tumbling mill apron belt, fixture of hooks or pockets, hanger with hooks, rotary table or tables, or pass-through roller or belt conveyor that transfer the work piece(s) through the blast zone.

3) Electrical System - The wiring, controls, and motors to power and safely operate the system.

4) Abrasive Reclaim System- Transfers the abrasive mix back to the Abrasive Storage Hopper.

5) Separation System - The method that the machine has to remove contaminate waste, broken down media or dust from the reusable "good" abrasive.

6) Abrasive Storage System - The storage hopper system that effectively provides consistent media to the blast wheel.

7) Ventilation System - The Dust Collection System provides negative pressure to the system to assure dust free operation as well as performs the pneumatic separation of the abrasive and waste mix.

Specific Description For This Machine:

1) Pictures for detail:

2) Technical data Sheet:

3) Spare parts:

On the basis of shot blasting machine, we also produce and offer most spare parts for the shot blasting machines. Such as, Blasting wheel assembly, bucket elevator, dust collectors, casting parts including distributors, blades, cntrol cages and guarding boards(protection liners) etc. This will help our clients to save cost and time looking for spare parts.

4) Application

Our shot blasting machines are widely used in the metal surface cleaning field. Such as rust removal, sand cleaning, oxide skin cleaning, burnishing and descaling for parts used in the fields of ship building, auto industry, bridge, machinery , auto parts, other casting parts, forging parts, engineering parts etc.

Packaging: 1. Small spare parts put in plywood wooden cases

2.Other parts is our company standard or according to customer requirements

Shipping: Container transport

OUR SERVICE:

- 1. Reply your inquiry in 24 working hours.

- 2. Experienced staffs answer all your questions in time.

- 3. Customized design is available.

- 4. Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

- 5. Special discount and protection of sales are provided to our distributor.

- 6. Professional factory: We are manufacturer, specializing in producing all kinds of Shot Blasting Machine & Molding Machine & Core Shooting Machine for more than 40 years, competitive with good quality.

- 7. As an honest seller, we always use superior raw material, advanced machines, skilled technicians to ensure our products to be finished in high quality and stable feature.

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

Welcome to contact us or visit our company.

BUYING LEADS:

If you are interested in our machine,please kindly inform us the following items:

- 1,The name of your workpiece?( such as: iron casting parts, Aluminium auto parts etc.)

- 2,The purpose of the blasting?(rust removal or others?)

- 3,The size range of the workpiece?( max size and min size)

- 4,The weight of the workpiece? (max weight and min.weight)

- 5,The cleaning capacity per day/month?

- 6, Any other technical requirement?

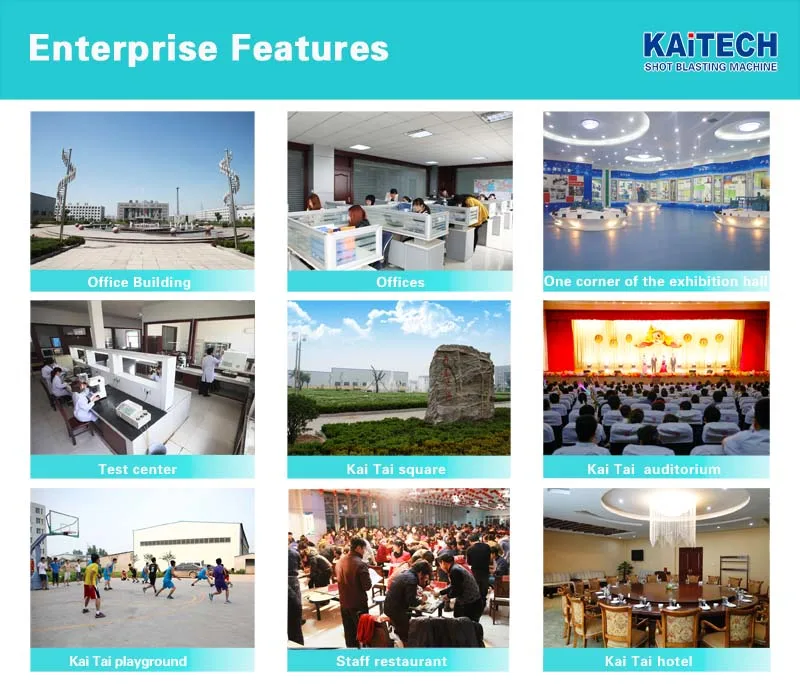

Shandong Kaitai Shot-blasting Machinery Co., Ltd. is the biggest enterprise of foundry machinery and foundry products in China which integrates with technical research, development, production, installation, debugging services and sales.

Our company is located in Zouping Fenghuang Economic Zone. The company occupies 150,000 square meters.

The company has the first-class Technology R&D Center and perfect quality management system. Meanwhile, we have passed ISO9001 International Quality System Certificate, ISO1400 Environmental Management System Certificate and CE Certificate. We also take part in and set down GB/T 23576-2009 "Shot Peening Equipment General Technical Condition".

All products adopt CAD/CAM computer aid design, and the appearance of products adopts three-dimensional software design and the key components adopt simulation analysis of finite numerical.

Our main products are shot blast machine, abrasive blasting equipment, sandblasting machines, steel shot blasting, environmental protection dust removing equipment, shot blasting machine spare parts and so on.

We provide ideal key equipment to casting, forging and heat treatment, steel structure, container, machinery, shipyard, locomotive industries. Our products have exported to more than 30 countries and regions.

Q 1: Do you have after-sale service?

A : yes, we do.

Q 2: How long can your spare parts be used?

A: Blade, control cage and distributor are high chrome, and can be used for more than 2000 hours.

Kinds of guard board can be used for more than 3000 hours.

Q3: What’s the nearest airport around your company?

A: The Jinan International Airport is the nearest arround our company. If you want to come to visit out plants, we can pick you up there. BTW, the nearest railway station for fast train is Jinan West Station. We can also pick you up from the station.

Q4: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q5: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q6: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q7: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

We are looking forward to doing business and making friends with you.

Q8: Other products:

A: We also provide foundery machine as below:

Stone shot blasting machine, Tumble Rubber type Surface cleaning machine for castings , spinner hook abrasive blast machine, hook shot blasting machine, rotaray table type shot blasting machine,

etc. and clay sand produce machine, resin sand produce machine, clay and resin sand regenerate machine, sand blasting machine, sand mixer, moulding machine, dust collector.

===============================================================================================

With over 8000 clients from nearly 40 countries and regions, we are the largest producer and supplier of shot blasting

machines and metal abrasives in China. Contact me if interested.

----------

Clive.Lee ( Export Manager)

Shandong Kaitai Shot Blasting Machinery Co.,Ltd |www.kaitaimachinery.com

Shandong Kaitai metal Abrasives Co., Ltd. | www.kai-tai.com.cn

Address: Qingyang, Zouping, Binzhou, Shandong, China Post code:256217

Tel: 86-531-88939198 | Fax: 86-531-88939198

Mobile: 86-15266743900 | Skype:susana666888