COMPANY INFORMATION

AFTER-SALES SERVICE

We keep good relationship with customers. We meet customer`s requirements. We insist on regular visits to provide the whole machine running report and innovative solutions for customer. It could improve equipment running performance and reduces running according to our services and maintance plan.

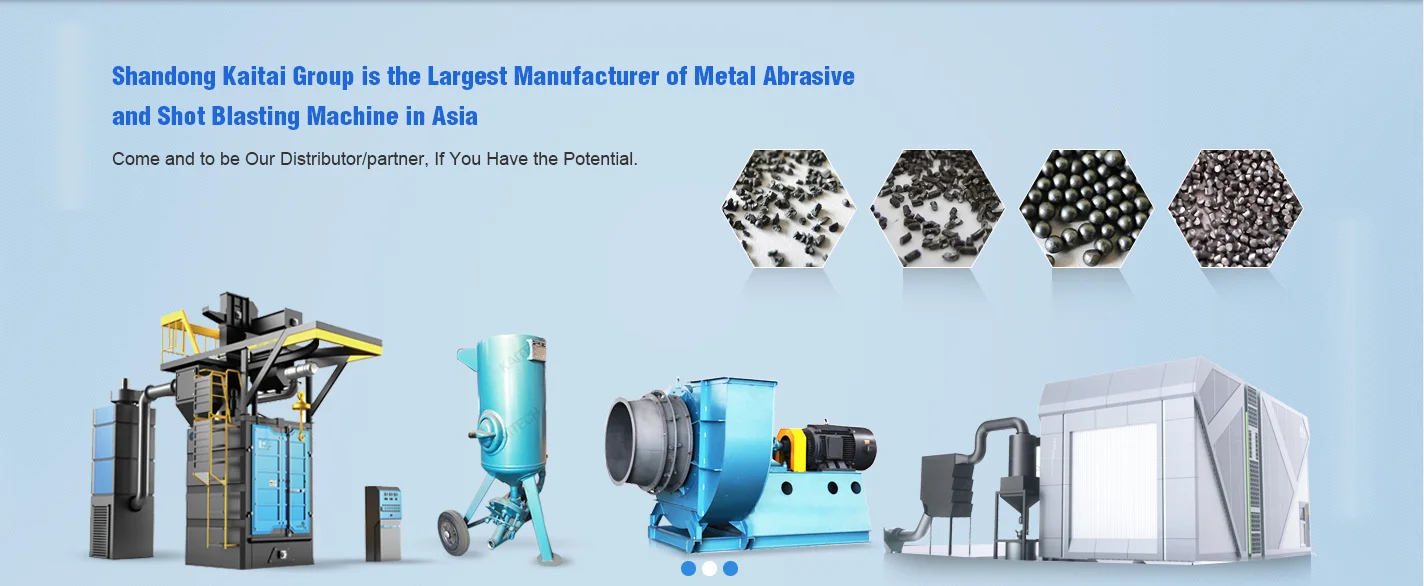

Products Description

Information Introduction:

The shot blast machine is suitable for surface cleaning and strengthening of medium or small size castings,forge pieces

and a variety of hardware.It is for different production capacity,the machine can be used not only as a single machine,but

also as a part of a line.The machine match with continuous conveyor composed cleaning productionline,it is a ideal

cleaning equipment for medium and large size cleaning workshop.

Advantage:

Tracked shot blast clean-up machine has advantages of advanced design,rational construction,low-power.

Q32 tumble shot blasting machine offers reasonable structure, low energy consumption and high efficiency. The blast

chamber is equipped with wear protection plate on the inner wall to avoid punctures due to shots at a high velocity. The

rubber belt conveyor allows easy tumbling of workpieces and has many shot leakage holes for the cycle of balls.

Technical parameters:

General Description For Shot Blasting Machines:

All Shot Blast Cleaning Machines include these basic design criteria:

1.Shot Blasting Chamber

The place of cleaning up the worckpieces. Include chamber guard, tracked and others.

2.Elevator Systerm

It is composed of the cycloid reducer, the upper and lower pulley, conveyor belt, hopper, shell and the tension device and other components.

3.Shot Blasting Wheel

The wheel(s) propels or throw(s)

the abrasive media.

4.Separation System

seperation of the steel shot, dust and wast scrap.

5.Dust Removing

The figure is below national standard GB16297-1996 Atmospheric Pollutants Comprehensive Emission Standard 100mg/m³.

Contact:

Emma

Phone Number: 00 86 159 6501 7762

WeChat: 00 86 15965017762

WhatsApp: 00 86 159 6501 7762

E-mail: export13@kai-tai.com.cn