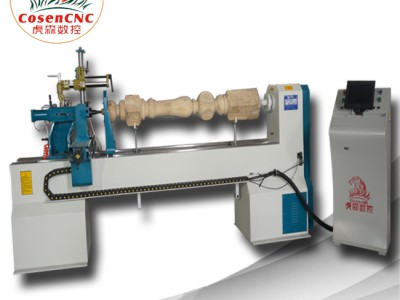

1.Driving system:Adopt frequency conversion speed regulation system, could adjust the turning speed at any time to solve the problem of materials’ vibration.

2.The machine has 2 cutters (The Rough turning cutter and finish turning cutter worksynchronously with layered process)

and so that improve the efficiency and workpiece surface quality.

3.Spindle: we could configure single spindle with two pcs cutter or one pc cutter, single spindle could configure chuck, two cutters could do rough turning and finish turning at the same time for high efficiency and surface quality. (Double spindles has stop to produce again. In fact,the modle is not good to the turning the wood products, it is very slow when turning the big sizes column, and there have many defects at design to the Double Spindle lathe, Such as the Sanding, Centering, Programming,Upper Spindle Structural Stability etc)

4.Linear square rails,ballscrews,and some electronic components are imported, high precision and durable.

5. Performance part: high accuracy stepper motor, after program calculating, guarantee the exact processing size.

6.Feeding part:Taiwan CSK high quality straight line sliding rails and TBI precise ball screw, control the linear error effectively.

7.High Class frequency converter with high stability

8.It is heavyduty and heavy weight with good stability,avoid shaking when the spindle rotates fast

or the big sizes workpiece process, and the main spindle speed can be adjusted through the frequency converter.

9.Easy operation, we can draw by Coredraw,Artcam,autoCAD and other softwares, and the control

directly by the CNC cabinet computer (Industrial PC configuration) or transfer the files to machine

by a USB (DSP handle configuration).

Application:

Various cylindrical workpiece, bowl sharp, tubular sharp and vehicle wood crafts, such as various staircase column, Roman column, general column, tables or chairs legs, washstand, wooden vase, wooden table, baseball bat, car wooden furniture, children' s bed column, etc.

Brand:

COSEN CNC - The first brand of CNC Woodworking Lathe in China and Multifunctional Wood Lathe manufacturing

expert symbol for the diversified market requirement . we focus on the high technic and quality for

the COSEN CNC brand rely on the Chinese sole Wood Lathe Research Institute of COSEN.

Nowadays,we have established lots of service network station across the country through decade

of years efforts.

Origin: Binzhou,Shandong,China.

(COSEN MFL™ - Turning + Milling + Twisted wire + Carving all-in-one CNC lathe)

|

Model |

CNC315S/K/W |

CNC415S/K/W |

CNC425S/K/W |

|

Max Processing Size |

1500x300mm |

1500x400mm |

2500x400mm |

|

Spindle Power |

4kw |

4kw |

5kw |

|

Quantity of spindle |

1 |

1 |

1 |

|

Quantity of tools |

2 |

2 |

2 |

|

Max feed speed |

35mm/s |

35mm/s |

35mm/s |

|

Spindle speed |

0-3500rpm |

0-3500rpm |

0-3500rpm |

|

Accuracy |

0.001mm |

0.001mm |

0.001mm |

|

Control system |

CNC,PC+12"LCD or DSP |

CNC,PC+12"LCD or DSP |

CNC,PC+12"LCD or DSP |

|

Support command |

G code |

G code |

G code |

|

Software |

Coreldraw,Artcam,Type3,Ucancam,Caxa,UG,Mastercam,AutoCAD |

||

|

Voltage |

380v/50hz |

380v/50hz |

380v/50hz |

|

machine dimension |

2750x1200X1300mm |

2750x1300X1400mm |

3750x1300X1400mm |

|

Weight |

1500kg |

1500kg |

2000kg |

S series : double turning tools wood turning lathe

K series: Multifunction woodworking machine, turning+engraving+slot+twist

W series: Multifunction woodworking machine, turning+engraving+slot+twist+carving plane

Optional part:

(1). Dust collect, which is used to collect the wood exhaust.

(2). Φ160 mm Four-Jaw Chuck for large sizes timber or barrel shape turning.

Consumable parts:

We suggest customers buy more consumable parts for future use.

(1). Tool. This machine use white steel tool. Customers could change the tools easily.

(2). Bearing. Customers could change the bearing easily.

(3). Centre rest bushing with 5cm and 6cm square timber.if have other sizes,please inform inadvance.

If you are interested in our any products, please do not hesitate to contact us.

For offer the exactly quotation timely. Please tell us more questions with RFQ as below:

1) Where's the working area? Such as Country or end-user place.

2) What kind of work do you want to do? Such as cutting column or engraving panel.

3) What's the workpiece material you want to process? Such as the wood species and the stock

thickness you want to process.

4) What's the sample do you want to engrave or cut? Such as sample name or pictures

We also welcome you to our factory for visiting,and the visiting ways as below:

Factory exact address:

Sujia Industrial Area, Huanghe 4th Rd.,Binzhou City,Shandong Province,China.

By plane: Beijing, Jinan, Qingdao Airport

By train: Zibo,Jinan Railway station