Wood shredder for cotton stalk

1. Characteristics of Wood shredder for cotton stalk:

1). Advanced structure and reliable technology

2). High throughput capacity and high quality chips

3). Low-maintenance and environment-friendly

4). Cost-efficient and space-saving

5). Chipping of all kinds of wood

6). Guaranteed long running time

7). Hydraulic control, simple operation, easy maintenance.

2. Using scope and purpose of Wood shredder for cotton stalk:

Scope: wood raw material: timber, processing residue (branches, batten, log core, building templates, roots, waste veneer etc.) particle board, fiber board.

Non-wood raw material: sugarcane, reed, bamboo etc.

Purpose: particle board factory, high density fiberboard, stubble factory, biomass power plant, wood factory.

3. Technical Parameters of Wood shredder for cotton stalk:

|

Type |

HX215 |

HX216 |

HX217 |

HX218 |

HX2110 |

HX2113 |

HX6213 |

|

Blade diameter (mm) |

500 |

650 |

650 |

800 |

1000 |

1300 |

1300 |

|

Blade number (piece) |

2 |

2 |

2 |

2 |

2x2 |

3 |

6 |

|

Input size (mm) |

180x400 |

240x540 |

240x680 |

310x680 |

330x1050 |

400x700 |

550x1480 |

|

Blade rotational speed (r/m) |

592 |

590 |

590 |

650 |

550 |

500 |

426 |

|

Rate of feeding (m/min) |

38 |

38 |

38 |

35-38 |

33 |

38 |

35 |

|

Max material diameter (mm) |

160 |

220 |

220 |

300 |

190 |

380 |

380 |

|

Wood chip length (mm) |

35 |

35 |

35 |

15-35 |

30 |

38 |

30-50 |

|

Capacity (t/h) |

6-8 |

8-12 |

8-15 |

10-15 |

11-15 |

20-35 |

35-50 |

|

Main power (kw) |

45 |

55 |

75 |

110 |

220 |

200 |

315 |

|

Power (kw) |

2.2*2 |

4+3 |

4+3 |

2*4 |

7.5x2 |

7.5x2 |

11+18.5 |

|

Weight (t) |

2.9 |

4.07 |

5.5 |

7 |

12.5 |

13 |

18 |

|

Size (mm) |

1540x1240x1350 |

1980x1950x1600 |

1980x2150x1250 |

2300x2150x1850 |

2850x2799x1497 |

3670x2448x2050 |

3670x3300x2050 |

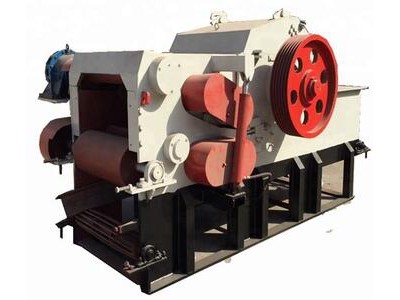

4. Picture of Wood shredder for cotton stalk:

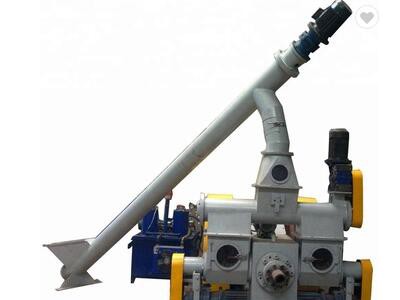

5. Working site of Wood shredder for cotton stalk:

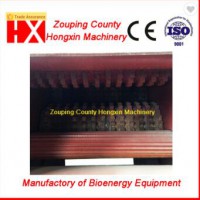

6. Good chipping quality of Wood shredder for cotton stalk:

7. Tips

In order to serve you better, please try to provide the below information:

1) What is the material to be crushed? If timber, what kind of wood?

2) Hardness?

3) Moisture content?

4) Maximum diameter of the material to be crushed?

5) Maximum length of the material to be crushed?

6) Required production capacity?

7) Required chips size?

8) What will wood chips be used for ? ( making wood pellets? For biomass power plant? Etc)

9) Working location of the machine?

10) Other special requirement which you think necessary to let me know?

Then I will recommend suitable model based on your actual needs.

Zouping County Hongxin Machinery:

2).Main products: Wood chipper, Sawdust machine, Drum dryer, Vertical ring die pellet machine (biomass pellet machine), Counter flow cooling separator, Packing machine; Comprehensive crusher, Building templates crusher, Plancon crusher (Stump grinder), Free move (Mobile) cutting machine (Brush chipper), Complete pellet production line.

3).Manufacture independently the key machines of pellet production line, can design complete production line according to customers’ needs.

4).Covers an area of 40,000 square meters, with more than 200 people including 120 specialized technicians and 8 senior engineers.

5).More than 100 sets of machineries of assembling, processing and transportation, etc.

6).Formed a complete systematic management system, can offer non-standard products according to customers’ request.

7).ISO9001certified. CE certified.

8).Provide clients with reliable and timely After-Sales Service and Technology Support.