|

Material |

6000 series Aluminium T4, T5, T6 |

|||

|

Size / Thickness |

1.General profiles thickness from 0.8 to 5.0mm, length from 3m-6m or customized available 2.Anodize protection film thickness from 8~25 um 3.Powder coating from 40 ~ 120 um.

|

|||

|

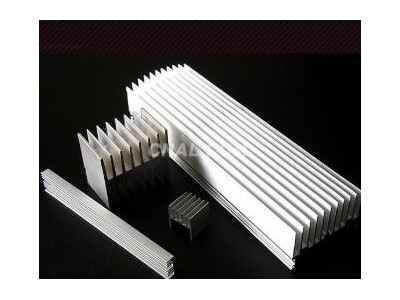

Shape |

square, round, t shaped, rectangular, customized |

|||

|

Surface treatment |

Mill finish,Anodizing,electrophoresis,powder coating,PVDF coating, wood transfer,polishing,brushing etc. |

|||

|

Colors |

silver , black , blue, wood color , RAL powder coating color and so on |

|||

|

MOQ |

500kgs for each item |

|||

|

FOB Port |

Dalian/ Shanghai/Tianjin /Guangzhou |

|||

|

payment terms |

T/T 30% for deposit, balance before shipping. |

|||

|

settlement term |

Charge by final actual weight or by drawing theoretical weight. |

|||

|

Certificate and Standard |

CQM, SGS, CE, BV, SonCAP / GB, ISO, JIS, AS, NZS, QUALICOAT, QUOLANOD available |

|||

|

Production Capacity |

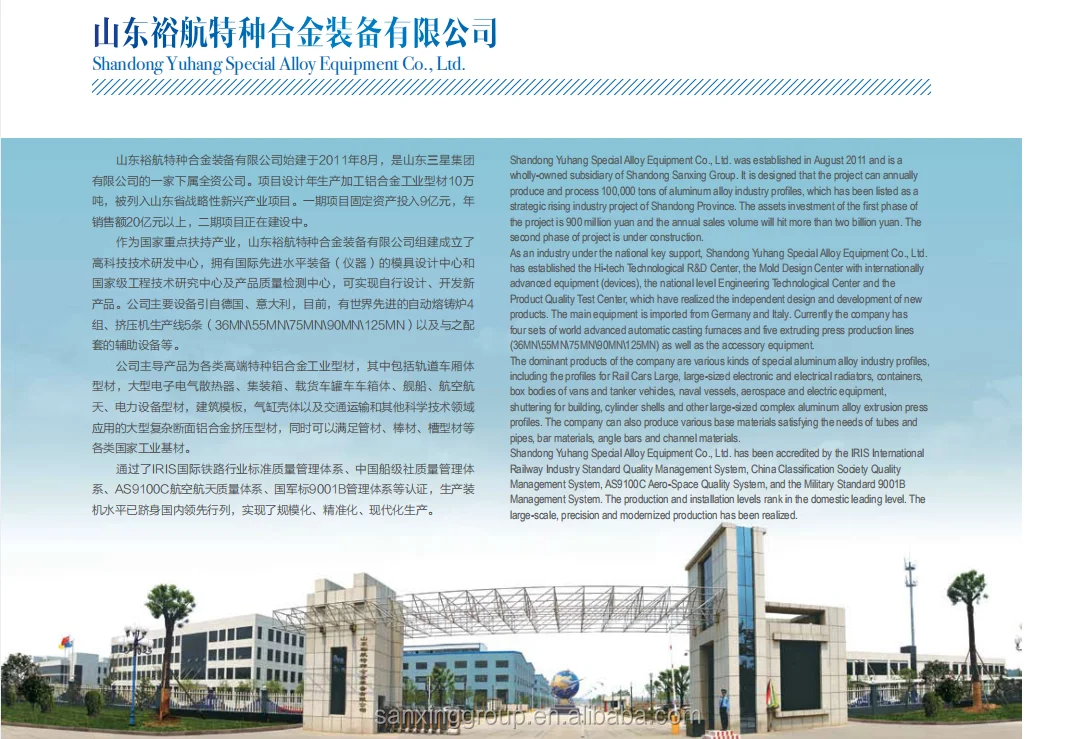

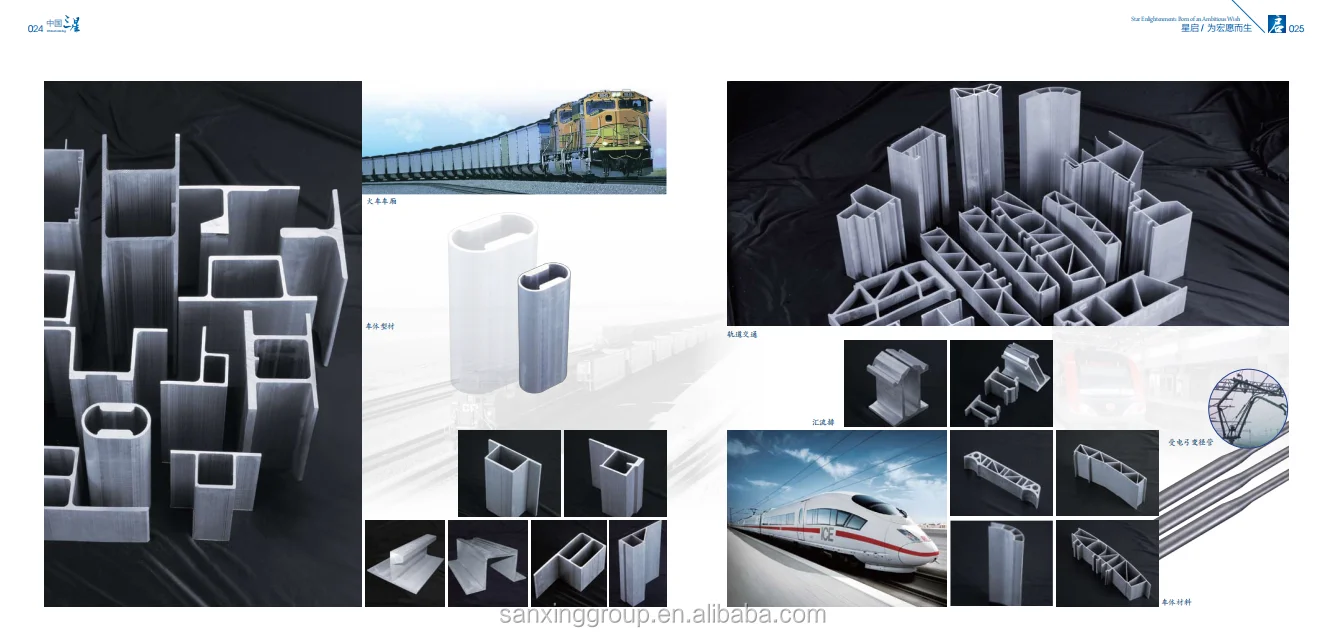

||||

|

Max production capacity(tons/year) |

150000 |

|||

|

Extrusion equipment |

Max |

Min |

Quantity |

|

|

|

9000 Tonnage |

660 Tonnage |

10 sets |

|

|

CNC Machine |

32 sets |

|||

|

Punching Machine |

10 sets |

|||

|

12 meter long CNC Machine |

1set |

|||

|

Drilling Machine |

10 sets |

|||

|

Anodized Line |

2 sets |

|||

|

Powder coated Line |

2 sets |

|||

|

Imitated Wooden Line |

1 set |

|||

|

eletropheresis line |

1 set |

|||

|

Packing and shipment |

|

|

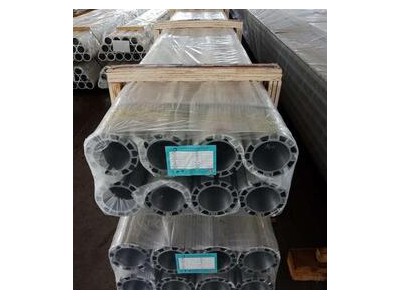

Packing |

1.Plastic film& kraft paper packing. |

|

|

2.Plastic bag packing. |

|

|

3.Carton packing$ plywood. |

|

|

4.Plastic film$ pallet. |

|

shipment |

1.By Sea |

OEM Service

Step 1: Send us the authorization letter of using your brand name.

Step 2: We will design teh packing version logo under your request.

Step 3: Confirmation on the version charge.

Step 4: We provide the OEM service for your products.

ODM Service

Step 1: Send your detail drawing or physical samples to us.

Step 2: Our emgineer will make design based on your drawings or samples.

Step 3: Details quotation for both mould and products.

Step 4: Test our product samples for /confirm/iation.

Step 5: After confirmation on samples, we can start mess production.