Product Description

The Major Technological Index:

Application:

Blast cleaning of cast steel grit:Used for blast cleaning of casting, die-casting, forging, sand removal of casting, steel plate,

H type steel, steel structure. Rust removal of cast steel grit:Rust removal of casting, forging, steel plate, H type steel, steel structure, descaling of?forging.Shot blasting of cast steel grit:Shot blasting of profile steel, ship board, steel board, steel material.

Shot blasting of cast steel:Shot blasting of steel board, profile steel, steel structure.

Pre-treatment of cast steel grit:Pre-treatment of surface, steel board, profile steel, steel structure, before-painting.

Steel Grit Types:

GP:Angular when new, this grit rapidly rounds off in use and its particularly suited descaling applications.

GL:Although harder then GP steel grit, also loses its sharp edges during shto basting and is particularly suited to descaling and surface preparation applications.

GH:Having maximum hardness, GH always remains angular in its operating mix. These abrasive are particularly effective in surface treatment processes and produce a uniform, etched finish, GH angular grit should only be used in wheel machines where working requirements take precedence over cost price considerations (for example with rolling mill cylinders or when a special finish is needed). For use mainly with compressed air equipment.

GL:Although harder then GP steel grit, also loses its sharp edges during shto basting and is particularly suited to descaling and surface preparation applications.

GH:Having maximum hardness, GH always remains angular in its operating mix. These abrasive are particularly effective in surface treatment processes and produce a uniform, etched finish, GH angular grit should only be used in wheel machines where working requirements take precedence over cost price considerations (for example with rolling mill cylinders or when a special finish is needed). For use mainly with compressed air equipment.

Packing & Delivery

General Packing :

a. 25kg per bag ,40 bags in one pallet

b. 25kg per bag ,40 bags in one jumbo bag

c. 25kg per paper bag ,40 bags in one plywood pallet

d. One ton a bulk bags

Special Packing: According to customers’ requirement

Delivery : Within 3-7 days after the payment

b. 25kg per bag ,40 bags in one jumbo bag

c. 25kg per paper bag ,40 bags in one plywood pallet

d. One ton a bulk bags

Special Packing: According to customers’ requirement

Delivery : Within 3-7 days after the payment

product processing

With strong technical force, advanced equipments such as intermediate frequency induction furnace, centrifugal atomizer,second quenching, tempering, spiralizing, package and so on, the company could produce high strength,strong durability cast steel shot and cast steel grit.

Certifications

1.GB/T18838.3-2008 High carbon cast steel shot and grit

2.SFSA20-66 Cast steel abrasive

3.SAE J827 cast steel shot

4.SAE J1993 High carbon cast steel grit

5.YB/T5149-1993 cast steel shot,cast steel grit

6.GB/T18838.4-2008 Low carbon cast steel shot

7.ISO11124-3 high carbon cast steel shot and grit

8.GB/T18838.5-2015 steel cut wire shot

9.JB/T8354.1-2013 steel cut wire shot

10.JB/T8354.2-2015 High carbon cast steel shot

11.JB/T 8354.3-2015 High carbon cast steel grit

12.JB/T 8354.4-2015 Low carbon cast steel grit

13.JIS G5903 High carbon cast steel shot cast steel grit

14.SAE AMS2431/4C Purified Stainless Steel Cut Shot

15.SAE J441 steel cut wire shot

2.SFSA20-66 Cast steel abrasive

3.SAE J827 cast steel shot

4.SAE J1993 High carbon cast steel grit

5.YB/T5149-1993 cast steel shot,cast steel grit

6.GB/T18838.4-2008 Low carbon cast steel shot

7.ISO11124-3 high carbon cast steel shot and grit

8.GB/T18838.5-2015 steel cut wire shot

9.JB/T8354.1-2013 steel cut wire shot

10.JB/T8354.2-2015 High carbon cast steel shot

11.JB/T 8354.3-2015 High carbon cast steel grit

12.JB/T 8354.4-2015 Low carbon cast steel grit

13.JIS G5903 High carbon cast steel shot cast steel grit

14.SAE AMS2431/4C Purified Stainless Steel Cut Shot

15.SAE J441 steel cut wire shot

company information

Shandong Kaitai Group

SHANDONG KAITAI GROUP is the biggest manufacturer of metal abrasive,shot blasting machine,wear-resistant parts,ect.in China which integrates with technical research,development and production.As well as the supplier of providing comprehensive shot-peening and shot blasting solusion.At present,our metal abrasive industry(is in the leading position of ranking) has already ranked fourth in the world,the first in Asia.

Branch company:Shandong Kaitai metal Abrasive Co.,Ltd.

We are the biggest manufacturer of metal abrasive in Asia which intergrates with technical research,development and production,and provides solution for omnidirectional shot blasting and sand peening technology.The main products of Shandong Kaitai metal Abrasive Co.,Ltd is Cast steel shot Series , Cast steel grit Series ,Stainless Steel Cut Wire Shot Series and Stainless Steel Shot Series.

Official website:www.kai-tai.com.cn/

Official website:www.kai-tai.com.cn/

Main Product : Cast Steel Shot,Cast Steel Grit, Steel Cut Wire Shot, Stainless Steel Shot, Stainless Steel Cut Wire Shot, Aluminium Shot , Zinc

Shot , Copper Shot.

Shot , Copper Shot.

Our Service

1. Free Sample: 200g Sample free for the customers.

2. Free Testing : We can test the sample for customers for free.

3. Welcome visit the factory , we will show you the Production Workshop and Exhibition hall

4. Quality service:our product has met ISO & SAE certificate.

5. Free Professional Technical Consultation Services

KAITAI is not only dedicated to the production and supply of shot blasting equipment , abrasive media and metal castings, but also focused on product R&D. So,we offer professional technical consultation services for global customers.

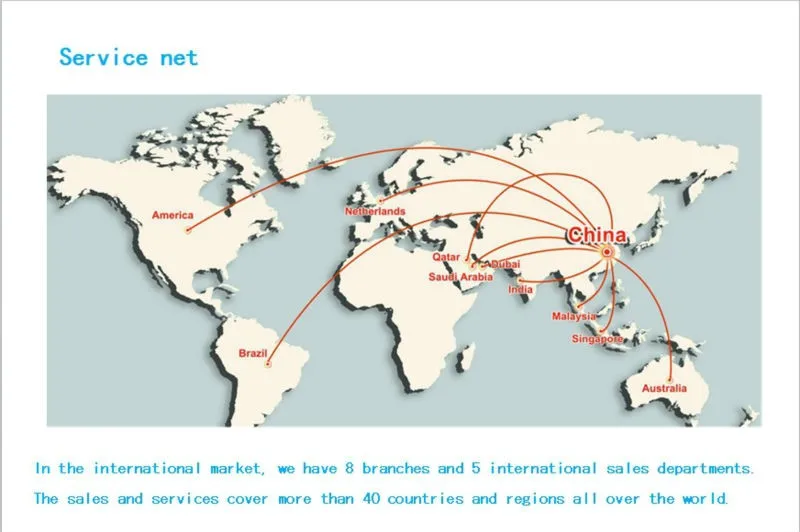

6. Quick After-Sales Service: Our company has equipped with many offices all over the world , will quickly help you if there are any question with the product.

Our sales network covered global,now we have 17 sales branch offices,and 55 offices.Now our customers are more than 6000,then we

have exported to Japan,Singapore,India,the Middle East,Malaysia,Brazil,Indonesia Australia and so on.

2. Free Testing : We can test the sample for customers for free.

3. Welcome visit the factory , we will show you the Production Workshop and Exhibition hall

4. Quality service:our product has met ISO & SAE certificate.

5. Free Professional Technical Consultation Services

KAITAI is not only dedicated to the production and supply of shot blasting equipment , abrasive media and metal castings, but also focused on product R&D. So,we offer professional technical consultation services for global customers.

6. Quick After-Sales Service: Our company has equipped with many offices all over the world , will quickly help you if there are any question with the product.

Our sales network covered global,now we have 17 sales branch offices,and 55 offices.Now our customers are more than 6000,then we

have exported to Japan,Singapore,India,the Middle East,Malaysia,Brazil,Indonesia Australia and so on.