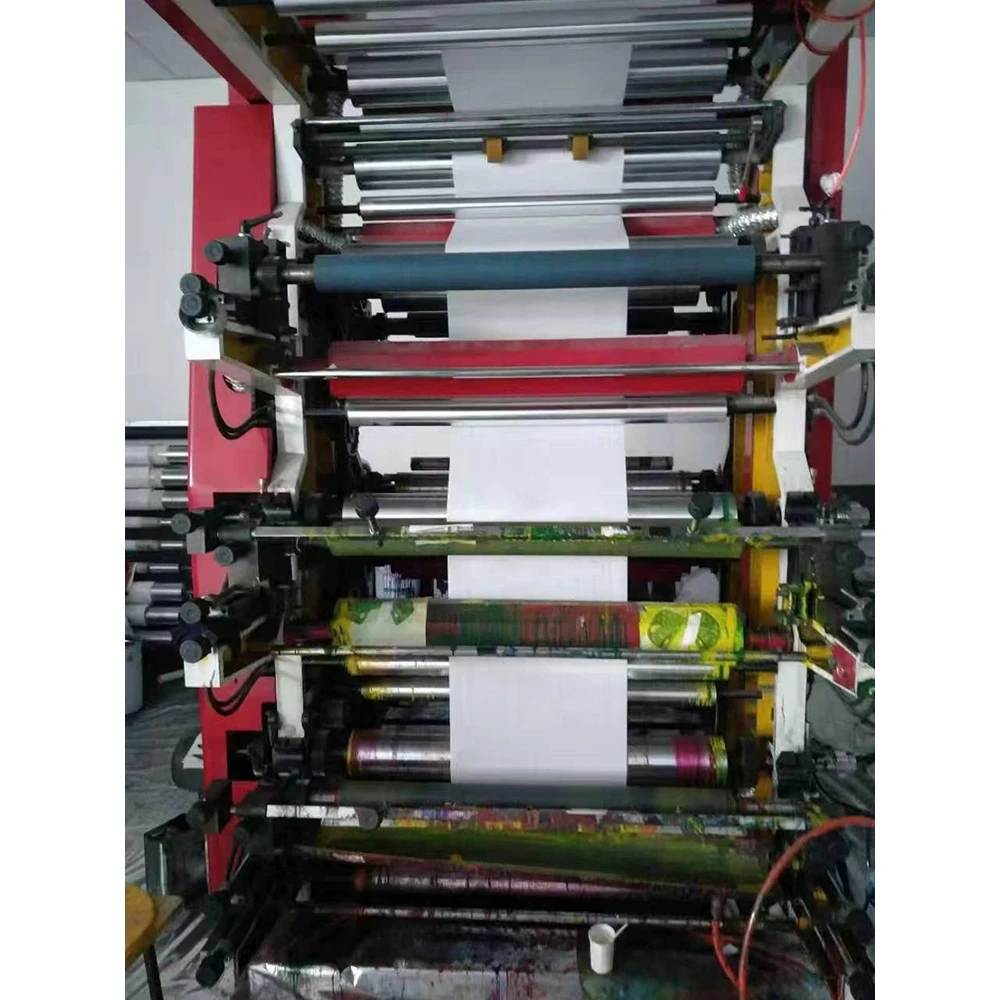

Used 6 colour flexo printing machine

Printing color: 6 colors

Maximum material width: 1000mm

Maximum mechanical speed: 100 m / min

Maximum printing speed: 30-70 m / min

Registration accuracy: Vertical ± 0.15mm (manual) Horizontal ± 0.15mm (manual)

Rewinding and unwinding diameter: φ800 mm Retractable reel/cylinder: φ76 mm (inside diameter)

Imprinting force: mechanical adjustment

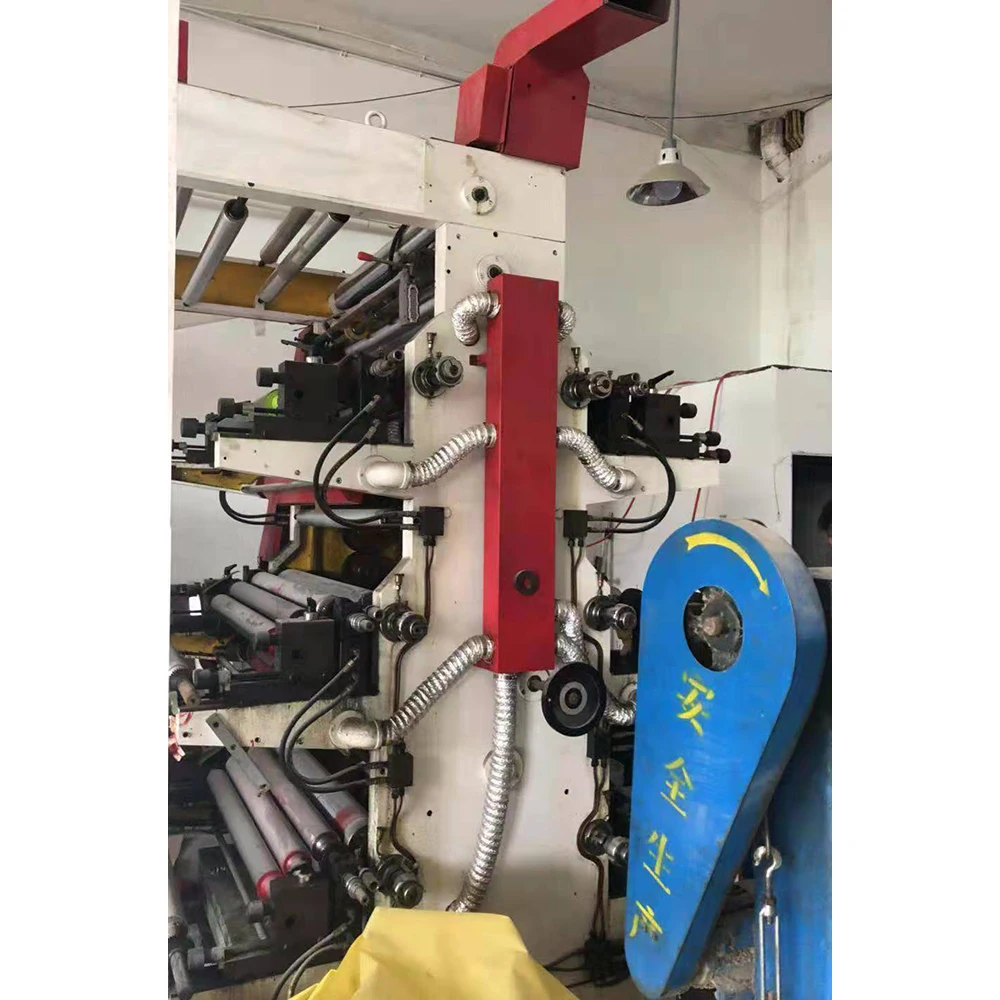

Up and down version: Fully automatic hydraulic landing

Anilox roller: 4 imported ceramic anilox rolls

Tension mode: receiving/discharging all controlled by automatic tension detection system

Putting/winding method: using gas rising shaft to clamp material, 10 kg magnetic powder, and another set of 2.2 kW motor combination winding

Edge correction method: automatic photoelectric edge correction system

Drying method: electric heating

Drying power: 12KW (special double-sided blowing, faster drying)

Air blower: 1.1KW × 2 1.5KW × 2 main frequency conversion: Frequency converter speed regulation

Ink motor: Geared motor (0.2KW)

Switchboard power: 24KW

Bearing: Japan NSK one-way bearing Germany ASNU aluminum alloy guide wheel for hard oxidation, dynamic balance, static balance treatment

Scope of application: paper printing

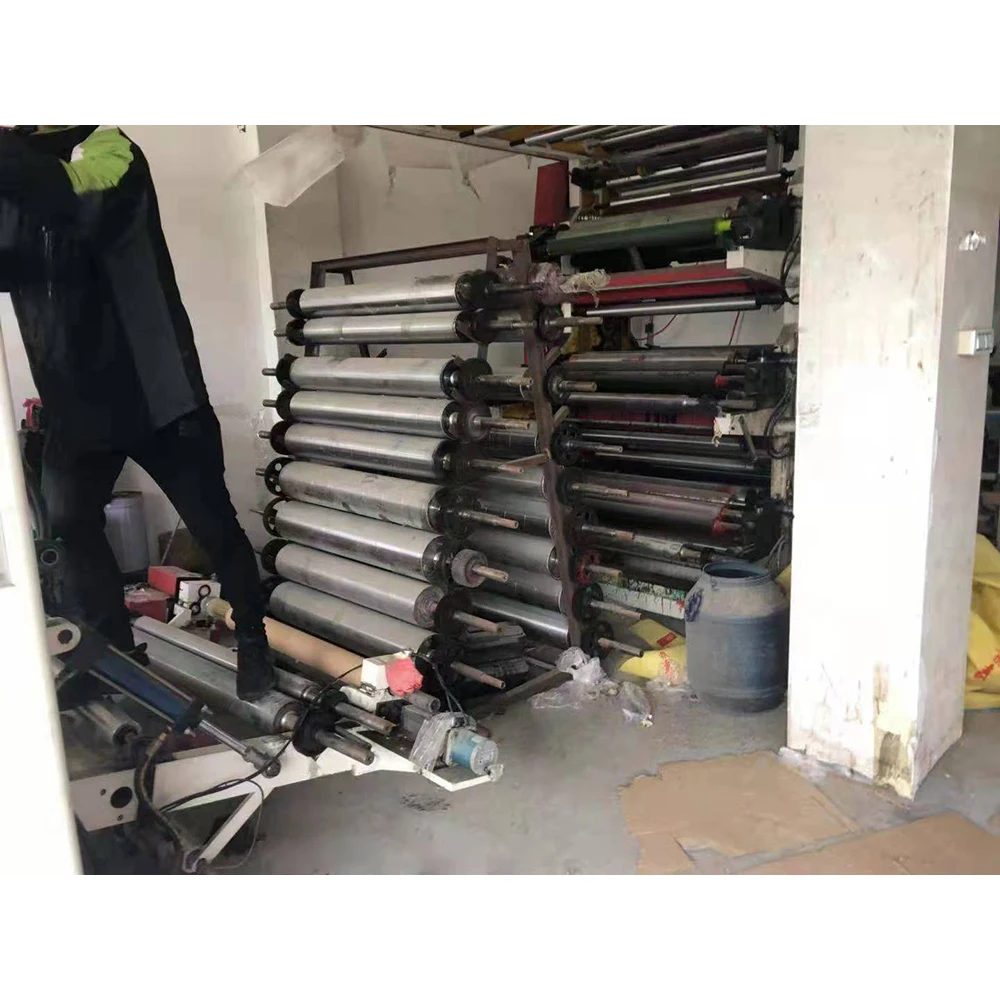

Number of plate rolls: 24

Main features:

1. Simple operation, accurate color registration and long service life

2. Adopt motor, frequency conversion speed regulation, save electricity, small fluctuation of operation

3. The printing plate automatically stops the ink motor, and the printing device automatically starts the ink discharging device.

4. It adopts special modulus helical gear transmission, and the printing size is accurate.

5. There are two sets of devices for blowing and heating, wherein the heating adopts a central constant temperature control system and is controlled by group.

6. The low roll is processed with special steel and processed by special process and electroplated with 10 wire thick hard chrome protective layer.

7 Aluminum alloy guide wheel for hard oxidation, dynamic balance, static balance treatment

8 With cold air shaping bellows, it can effectively prevent defects such as ink sticking after printing.

9. The printed image is clear and the layering is strong.