Liquid expansion fruit bag filling machine

1.Beautiful design

2.Low cost investment

3.Easy operate&maintenance

4.High Speed

Liquid expansion fruit bag filling machine

Technical Features

Pre-formed bag, vacuum pressurized filling is now the prevailing liquid packing method adopted in soft package industry throughout the world. It features novel style of packing, attractive shapes, reliable countering, firm sealing,easy operation, and lower cost of packing materials. It is widely used for packing milk, yogurt, and mineral water-under vacuum condition to avoid secondary pollution.

It is provided with dedicated computer-based controller and pneumatic device imported from abroad to complete constant filling and automatic sealing.

TB series automatic liquid hot-filling machine is suitable for fruit juice, milk, jelly, tea drinks, flavoring water that need hot-filling. It also can be used for normal temperature filling. TB series can complete constant filling, sealing and drop-down bag automatically. With advantages of small size, easy operation, energy saving, easy maintenance etc, it's the best choice for hot-filling of the various shapes of expansion bag.

export standard high configuration

1adopts PLC

2material: 304 stainless steel

3speed:1000-3000bags/hour

4capacity:500-1000ml

water bag packing machine is used for preformed bags(inflation bags,bar milk bags,bar yogurt bags),auto filling sealing in the airless condition.It is widely uaed in dairy,beverage,liquid spices,soy produducts,jelly,wine,detergents,semi-fluid,liquid chemical,high viscosity semifluid product,grain orange product,coconut,pulp milk,alcohol cream ect.it adopt touch screen PLC controled system.solving the problem of artificial can not be hot filling avoiding secondary pollution.

1.Adopt PLC controled,one to one cylinder pneumatic sealing .completely replaced the spring sealing.

2.Through the button to chang the number on the touch screen to adjust the measure and make the number more accurate.

3.Adopt a special pressure filling pump feed.eliminating the notes plug pump caused low efficiency and big air consumption disadvantafe

4.for diffcult to seal forming bag,except the conventional tempreture control system ,we also add time adjustment.

5.Nozzles adopt special design,Ensure the sealing consistency .

6.it can filling 2-8different flavors and colours liquid.

Notes:the same series of models,nozzles are divided into :4.12.16.24nozzles/set,ifyou need nore than 8 nozzles ,we recommend using rotary model(type B machine)

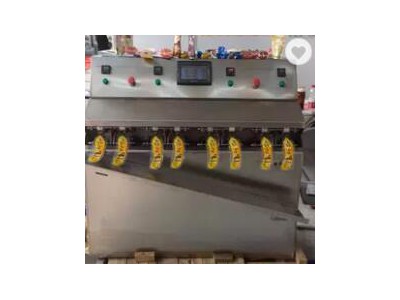

YHGZFJ-B-12

Power: 3.8KW

Speed:3000-6600pouch/hour

Capacity:50-1000ml(can be customized)

Coltage:220v 50HZ

Size:2020*1460*1880mm

This machine is the upgrade products of type A machine. In addition to have all the fuction of type YHGZFJ-A-8, it can rotary auto-filling and sealing, six group with 12 nozzles(output is equivalent to 24 nozzles),therefore greatly improve the production efficiency on the basis of saving artificial. This machine has won the national patent(patent NO.ZL200820141615.6)