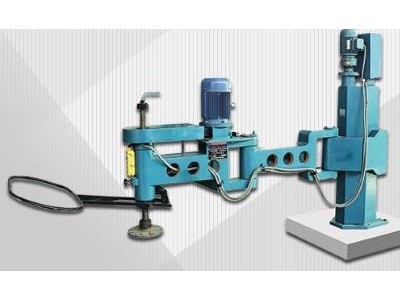

The whole electric control system of the infrared full automatic bridge trimming machine has passed the authoritative certification,and the safety factor of the electrical appliances is high, and the quality is more guaranteed.The main frame with four sliding pipes is formed in one body, which has high upper and lower stability and long service life. Adopting imported components and finishing accessories, the failure rate is low, the deformation is not easy, and the service life of the machine is prolonged. Workbench hydraulic lifting, convenient upper and lower plate. The host is faster, more accurate, faster positioning and faster moving.

The original operation interface is 5.7 inches. Now it combines 10.1 inch touch screen with traditional button. It has better visual effect, easier operation and more convenient maintenance. There are multiple operation modes in the operation interface, which have higher flexibility, more humanized operation, more time-saving and labor-saving, more convenient cutting and faster speed. In the process of increasing automatic cutting, the functions of increasing, reducing, checking, correcting size and quantity in the middle, and returning to the position of the last cross beam after emergency stop can be realized.

Product Parameter of the Infrared Full Automatic Bridge Trimming Machine

|

Saw blade movements itinerary |

500mm |

|

Saw blade diameter |

Φ400mm-Φ800mm |

|

Table size (L×W) |

3200×2000mm |

|

The workbench rotation angle |

0°-90°-360° |

|

Main motor power |

18.5kw |

|

Table vertical plate turning angle |

0-85° |

|

Water consumption |

4m³/h |

|

Dimension(L×W×H) |

6000×5000×2800 |

Product Feature and Application of the Infrared Full Automatic Bridge Trimming Machine

This machine adopts the whole girder automatic displacement, imported electrical parts and high precision spare parts, greatly improving the processing accuracy and stability. It is an ideal equipment for cutting high-value and large-size sheets.

The produced by our company is controlled by micro-computer. The saw blade can rotate up to 50 degrees in the stereo plane. The matching worktable can rotate 360 degrees in the horizontal plane and locate at 45 degrees (jumping angle) and 85 degree turning plate.

Precision manufacturing and assembling, special side beam protection device and touch operation system make it have the characteristics of high precision, high stability, high efficiency and simple operation. Guiyang Infrared Cutting Machine is especially suitable for processing high-value and large-scale granite and marble slabs.

Production Details of the Infrared Full Automatic Bridge Trimming Machine

1. All electronic control systems adopt high-quality components-PLC using Taiwan Yonghong, frequency converter using Japan, contactor using Siemens and so on.

2. The positioning dimension accuracy adopts the magnetic grating ruler made by SIKO, Germany, and has the advantages of positioning accuracy not affected by mechanical aging.

3. Control panel, input using touch screen input.

4. The contact surface between the lifting guide pillar and the mid-seat adopts the surface rolling guide sleeve (oil-free self-lubricating bearing) made of PTFE polymer material from DuPont, USA. The guide sleeve surface is rolled into a circular oil storage pit, which can work normally under the condition of less oil or gap oil breakage. It has the advantages of low friction coefficient, good wear resistance and long service life.

5. The fittings used in the fuel tank system are all made of high quality spare parts at home and abroad.

Infrared Marker.

Production Qualification of the Infrared Full Automatic Bridge Trimming Machine

FAQ

Q:What is the minimum order quantity?

A:Minimum order quantity 1set.

Q:When the manufacturers shipped the product?

A:The delivery term within 15 days after get the down payment.

Q:What kind of payment do I use?

A:Payment Irrevocable L/C at sight or T/T (30%down payment and 70%balance payment against the scan B/L).

Latest News

Looking at the current situation of stone mines in China, the only way to get rid of the backward outlook of stone mines in China lies in two key factors: one is to carry out standardized stone mining process, the other is to carry out special mechanical mining based on standardized mining process.

Special stone mining machinery has been widely used in foreign countries such as Italy, Finland, the United States and so on. In addition to conventional advanced stripping, lifting and transportation equipment, special mining equipment has been adopted to meet the technological needs, such as vertical drilling, horizontal drilling, hydraulic drilling rig, hydraulic roof machine, high-pressure roof gas bag, water bag of high-pressure roof plant, high-pressure water cutter, flame cutting. Cutting machine, diamond bead rope saw, diamond chain arm saw, diamond band arm saw and so on. The application of these special equipment in key technology is undoubtedly the basis of leading mining enterprises in China. According to the data, the annual per capita labor productivity of foreign advanced mines is as high as 3000M3, which is an unimaginable index in both marble mines and granite mines in China. However, due to the high price of this series of special equipment, such as the introduction and application, domestic enterprises can not afford to adapt to China's national conditions.

In view of the current situation of domestic stone mines and in order to revitalize the development of stone mines, Chinese stone mining professionals have always been committed to the exploration of new technologies and the research and development of special mining equipment for stone mining, and made breakthroughs in related fields. Among them, Rongcheng Zhonglei Stone Material Co., Ltd. of Gaoshi Stone Group, relying on rich mining experience, has been exploring continuously for nearly 20 years. On the basis of learning and digesting advanced foreign technology and based on national conditions, it has taken the lead in successfully developing cylinder-controlled vertical drilling rig, chain-driven automatic multi-functional drilling rig, cylinder-type down-hole multi-functional drilling rig, chain-driven multi-functional down-hole drilling rig and hydraulic roof rock drill. A series of special mining machines for stone mines, such as flame cutter, automatic diamond bead rope saw, etc., have matured in technical performance and can completely replace similar products abroad, such as Italy, and have formed batch production capacity, which has been widely adopted by domestic selected mining enterprises. Successful development and extensive application of a series of stone mining equipment indicate that the overall level of China's stone mines is gradually narrowing the gap with foreign countries, which will certainly have a positive role in promoting the mining of China's stone mining areas and far-reaching significance.

Relatively speaking, the technical problems that restrict the development of stone mines are easy to eliminate, but the most important obstacle to the popularization of mining mechanization is the conservatism of mining enterprises themselves and the weak awareness of resources. Therefore, we should carry out mechanized mining of stone mines in China. It is still a long way to go to consolidate the solid foundation for the sustainable development of stone industry.