Introduction:

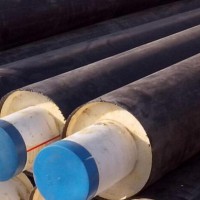

seline; background-image: initial; background-position: initial; background-size: initial; background-repeat: initial; background-attachment: initial; background-origin: initial; background-clip: initial;">1.Material: PE80/ PE100

2.Sizes: 20mm--1000mm

3.Pressure: 0.4Mpa, 0.6Mpa, 0.8Mpa, 1.0Mpa, 1.25Mpa, 1.6Mpa

4.Color: Black or others on request

5.Connection: Socket-fusion jointed, butt-fusion jointed , electric-fusion jointed, flanged jointed

6.Standard: GB/T 13663-2000

7.Certification: ISO9001, ISO14001

8.Application: Water supply, Industries liquids transportation , sewage conduit

ADVANTAGES:

1.Non-toxic, no heavy metal additives, no fouling, no breed bacterium,

2.Corrosion resistant: PE is inert material and it can resist the corrosion of many chemical mediums,orelectron chemical corrosion. except for few strong oxidants

3.High strength, good performance to resist the environmental stress cracking, good creep

resistance,

4.Good flexibility: small diameters PE pipe for water supply can be coiled and supplied for longer length, which saves a large number of fittings , PE pipe can be easily shifted according to

requirement of the projects.

5.Light weight ,simple safe and reliable welding technique,convenient construction and lower cost of the whole engineering,

6.Smooth interior wall, small water resistance, high flow capacity,

7.Long service life :up to 50 years under normal conditions.

8.Recyclable: friendly to the environment

Technical parameters of hdpe polyethylene pipe:

|

Item |

Unit |

Standard |

Testing Standard |

|

density |

kg/m³ |

≥940 |

GB/T1033 |

|

tensile yield strength |

Mpa |

≥19 |

GB/T8804.2 |

|

elongation at break |

% |

≥350 |

GB/T8804.2 |

|

longitudinal shrinkage rate |

% |

≤3 |

GB/T6671.2 |

|

environmental stress cracking restance |

h |

≥300 |

GB/T1842 |

|

the inner surface corona |

Dyn/cm |

≥50 |

EN253 |

|

long term mechanical properties |

1500h |

no damage |

CJ/T114 |

VARIOUS DIAMETER AVAILABLE FROM OUR FACTORY:

|

DN(mm) |

HDPE outer protection pipe |

||

|

diameter(mm) |

thickness(mm) |

weigtht(kg/m) |

|

|

25 |

90 |

2.5 |

0.66 |

|

40 |

110 |

2.5 |

0.81 |

|

50 |

120 |

3 |

1.06 |

|

70 |

140 |

3 |

1.24 |

|

80 |

150 |

3 |

1.33 |

|

100 |

180 |

3 |

1.6 |

|

125 |

225 |

3.5 |

2.34 |

|

150 |

250 |

3.9 |

2.89 |

|

200 |

315 |

4.9 |

4.58 |

|

250 |

365 |

5.6 |

6.07 |

|

300 |

420 |

7 |

8.72 |

|

350 |

500 |

7.8 |

11.58 |

|

400 |

560 |

8.8 |

14.63 |

|

450 |

600 |

8.8 |

15.69 |

|

500 |

655 |

9.8 |

19.07 |

|

600 |

760 |

11.5 |

25.96 |

|

700 |

850 |

12 |

30.33 |

|

800 |

960 |

14 |

39.94 |

|

900 |

1055 |

14 |

43.95 |

|

1000 |

1155 |

14 |

48.18 |