Introduction:

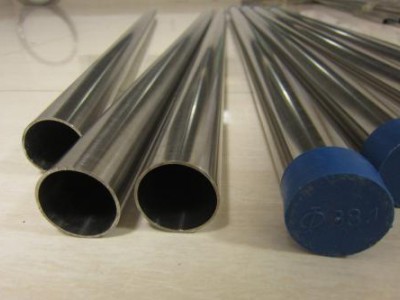

Cold-rolled precision seamless steel pipe (GB3639-2000) is a seamless steel pipe with high dimensional accuracy and good surface finish for precision mechanical structures, hydraulic equipment or steel sleeves.

Features:

High precision. There are usually two production processes of two-high rolling mill and three-high rolling mill. The precision of cold-rolled seamless steel pipe produced by three-high rolling mill is higher, which can be controlled within a few wires, but the price is relatively higher. The hot-rolled pipe adopts high-quality coils. After the re-inspection is qualified, the slitting or strip coils are automatically formed and welded. While the computer controls the optimal fusion temperature, the internal and external burrs of the steel pipe are removed, and the steel pipes that have passed the non-destructive test are rarely oxidized. The whole is heated to 910℃-950℃ in a high temperature atmosphere, and then the descaling is rolled by a tension reducing machine for multiple passes to make the metallurgical structure, grain state, geometric size and mechanical properties of the steel tube uniform. The products comply with API SPEC 5L, API SPEC 5CT, EN10217 standards. This product is widely used in flammable and non-flammable fluid transportation pipelines, boilers, and steel structures. Products fill the gaps in domestic production.