Introduction:

At present, my country's alloy pipe consumption accounts for only half of the total steel volume in developed countries. The expansion of the use of P22 alloy steel pipes provides a broader space for industry development. According to the research conducted by the Alloy Pipe Branch of the China Special Steel Association, in the future, the demand for long alloy steel pipes in my country will increase by 10-12% annually.

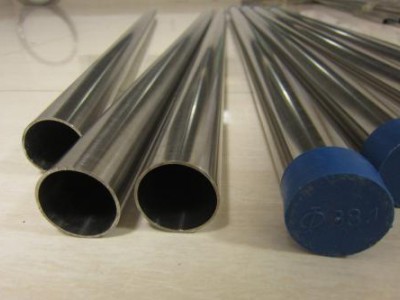

Seamless steel pipe:

Because of their different manufacturing processes, they are divided into two types: hot-rolled (extruded) seamless steel tubes and cold-drawn (rolled) seamless steel tubes. Cold drawn (rolled) tubes are divided into round tubes and special-shaped tubes.

a. Process overview

Hot rolling (extruded seamless steel tube): round tube billet → heating → piercing → three-roll cross rolling, continuous rolling or extrusion → tube removal → sizing (or reducing) → cooling → billet tube → straightening → water pressure Test (or flaw detection) → mark → warehousing.

Cold drawn (rolled) seamless steel pipe: round tube billet → heating → piercing → heading → annealing → pickling → oiling (copper plating) → multi-pass cold drawing (cold rolling) → billet tube → heat treatment → straightening → Hydraulic test (flaw detection) → mark → warehousing.

b. Seamless steel pipes are divided into the following varieties due to their different uses:

GB/T8162-1999 (Seamless steel pipe for structure). Mainly used for general structure and mechanical structure. Its representative materials (brands): carbon steel 20, 45 steel; alloy steel Q345, 20Cr, 40Cr, 20CrMo, 30-35CrMo, 42CrMo, etc.

GB/T8163-1999 (Seamless steel pipe for conveying fluid). Mainly used in engineering and large equipment to transport fluid pipelines. The representative material (brand) is 20, Q345, etc.

GB3087-1999 (Seamless steel tubes for low and medium pressure boilers). Mainly used in industrial boilers and domestic boilers to transport low and medium pressure fluid pipelines. Representative materials are 10 and 20 steel.

GB5310-1995 (Seamless steel tubes for high-pressure boilers). Mainly used for high temperature and high pressure transmission fluid headers and pipelines in power stations and nuclear power plants. Representative materials are 20G, 12Cr1MoVG, 15CrMoG, etc.

GB5312-1999 (Carbon steel and carbon-manganese steel seamless steel tubes for ships). Mainly used for I and II pressure pipes for marine boilers and superheaters. Representative materials are 360, 410, 460 steel grades, etc.

P22 alloy steel pipe sales are mainly used to transport high temperature and high pressure pipelines.

GB9948-1988 (Seamless steel pipe for petroleum cracking). Mainly used in boilers, heat exchangers and fluid pipelines of petroleum smelters. Its representative materials are 20, 12CrMo, 1Cr5Mo, 1Cr19Ni11Nb, etc.

GB18248-2000 (Seamless steel tubes for gas cylinders). Mainly used to make various gas and hydraulic cylinders. Its representative materials are 37Mn, 34Mn2V, 35CrMo, etc.

GB/T17396-1998 (Hot-rolled seamless steel pipe for hydraulic props). Mainly used to make coal mine hydraulic supports, cylinders and columns, and other hydraulic cylinders and columns. Its representative materials are 20, 45, 27SiMn, etc.

GB3093-1986 (High-pressure seamless steel pipes for diesel engines). Mainly used for high pressure oil pipe of diesel engine injection system. The steel pipe is generally cold drawn, and its representative material is 20A.

GB/T3639-1983 (cold drawn or cold rolled precision seamless steel pipe). It is mainly used for steel pipes for mechanical structures and carbon pressure equipment that require high dimensional accuracy and good surface finish. Its representative materials are 20, 45 steel, etc.

GB/T3094-1986 (cold drawn seamless steel pipe special-shaped steel pipe). It is mainly used to make various structural parts and parts, and its materials are high-quality carbon structural steel and low-alloy structural steel.

GB/T8713-1988 (Precision inner diameter seamless steel pipe for hydraulic and pneumatic cylinders). Mainly used to make cold drawn or cold rolled seamless steel pipes with precise inner diameters for hydraulic and pneumatic cylinders. Its representative materials are 20, 45 steel, etc.

GB13296-1991 (Stainless steel seamless steel tubes for boilers and heat exchangers). Mainly used in boilers, superheaters, heat exchangers, condensers, catalytic tubes, etc. of chemical enterprises. Used high temperature, high pressure, corrosion resistant steel pipe. Its representative materials are 0Cr18Ni9, 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti, etc.

GB/T14975-2002 (Stainless steel seamless steel pipe for structure). It is mainly used for general structure (hotel and restaurant decoration) and mechanical structure of chemical enterprises, which are resistant to atmospheric and acid corrosion and have certain strength. Its representative materials are 0-3Cr13, 0Cr18Ni9, 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti, etc.

GB/T14976-2002 (Stainless steel seamless steel pipe for fluid transportation). Mainly used for pipelines that transport corrosive media. Representative materials are 0Cr13, 0Cr18Ni9, 1Cr18Ni9Ti, 0Cr17Ni12Mo2, 0Cr18Ni12Mo2Ti, etc.

YB/T5035-1993 (Seamless steel pipes for automobile axle sleeves). It is mainly used to make high-quality carbon structural steel and alloy structural steel hot-rolled seamless steel tubes for automobile half-axle sleeves and drive axle axle tubes. Its representative materials are 45, 45Mn2, 40Cr, 20CrNi3A, etc.

API SPEC5CT-1999 (Casing and Tubing Specification) is compiled and published by the American Petroleum Institute (American Petreleum Instiute, referred to as "API") and used in all parts of the world. Among them: Casing: the pipe that extends from the ground surface into the well and serves as the well wall lining. The pipes are connected by couplings. The main materials are steel grades such as J55, N80, and P110, and steel grades such as C90 and T95 that are resistant to hydrogen sulfide corrosion. Its low steel grade (J55, N80) can be welded steel pipe. Tubing: A pipe inserted into the casing from the ground surface to the oil layer. The pipes are connected by couplings or integrally. Its role is to pump oil from the oil layer to the ground through the oil pipe. The main materials are J55, N80, P110, and C90, which is resistant to hydrogen sulfide corrosion, compiled and issued by the American Petroleum Institute, and are used all over the world.

Line pipe: The oil, gas or water that is output from the ground is transported to the petroleum and natural gas industrial enterprises through the line pipe. Line pipes include seamless pipes and welded pipes. The pipe ends have flat ends, threaded ends and socket ends; the connection methods are end welding, coupling connection, socket connection, etc. The main material of the tube is B, X42, X56, X65, X70 and other steel grades.