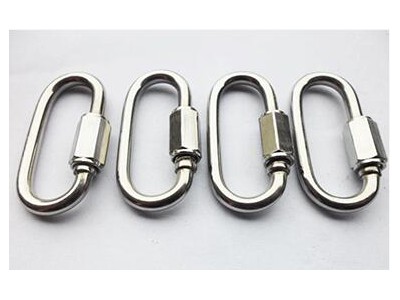

A kind of lifting equipment spreader.

General requirements:

1. The collar should be smooth and flat, without any cracks, flaws, sharp edges and uneven surface roughness that damage the wire rope. The tip of the loop should fit freely and shorten the tip to half the depth of the groove.

2. The surface of the collar should be hot-dip galvanized, and the surface should be smooth and flat, and there should be no defects such as missing plating, zinc particles, bubbles, cracks, etc. The galvanized layer should have sufficient adhesion strength during normal application.

3. The material of the collar can be A3 steel or 15,35 high-quality carbon steel.

4. The safety load of the collar should not be less than 32% of the minimum breaking force of the wire rope.

5. When in use, the selection of the collar should be consistent with the specifications of the wire rope (Attached Table 5), and the diameter of the shaft pin used should not be less than twice the diameter of the wire rope.

Inspection of collar:

1. The collar should be inspected by the technical inspection department of the manufacturer, and the product quality certificate should be attached.

2. The loop should be smooth and flat, and there should be no cracks, defects, sharp edges, and uneven surface roughness that damage the wire rope. The tip of the loop should fit freely, and the tip should be shortened to half the depth of the groove.

3. After the surface of the ring is galvanized, there should be no defects such as missing plating, zinc particles, bubbles, cracks, etc.

4. During the test, the safety load of the collar shall not be less than 32% of the minimum breaking force of the wire rope. After unloading, the inner width of the ring shall not be greater than 15% of the original size.

5. The collar should be marked with dimensions, manufacturing units, etc.