2018 new oil recycle activated bentonite fuller earth

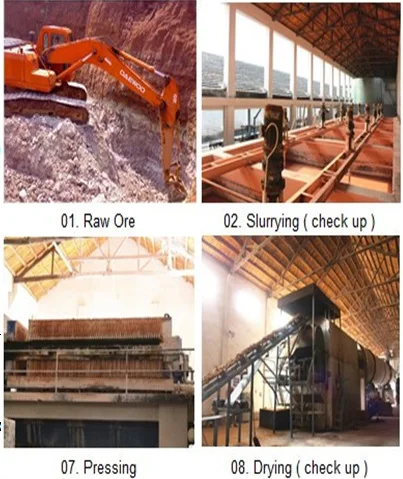

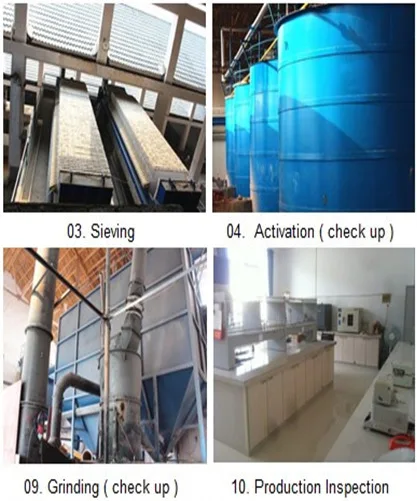

Production Progress

Bentonite fuller earth:

Characters

1) High bleaching efficiency

2) Low oil retention

3) Fast filltration rate

4) Ability minimise the increase of free fatty acids

5) Removing impurities like soap & trace metals

w/o affecting appearance, flavour & nutritional properties of Oil

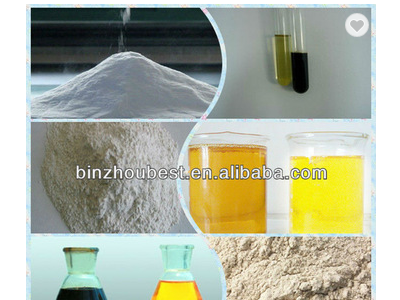

Application Fields

1)Decolorization of plant oils: soyabean oil,corn oil,palm oil,coconut oil, sunflower oil, peanut oil,cotton seed oil,olive oil, rice bran oil, castor oil, linseed oil, tung oil, rapeseed oil, etc.

2) Decolorization of mineral oils: Used lubricants oil,motor oil,engine oil,automative oil, paraffin wax,olefin,diesel, etc

3) Juice and wines’ clarifying.

4)medicine and environmental industries: Antidote and adsorbing materials, waste water treatment.

5) Enhance stability of the Refined Oil.

Physical specs (we can produce as per your request)

|

Partical size(-2μm) |

Min 95% |

|

Free acid(NaOH) |

Max 0.25% |

|

Moisture |

Max 9% |

|

PH |

4 |

|

Specific surface area |

285m2/g |

|

Density |

0.59 g/ml |

|

Heavy metal (pb) |

Max 0.005% |

|

Arsenic content |

Max 0.0005% |

|

Decoloring ability |

Min 92% |

important Points During Bleaching

1) Normally about 0.5%- 3% of earth is required for bleaching application of vacuum during process which results in less oxidation & improvement in oil colour.

2) Choice of bentonite fuller earth as per its characteristics.

3) Total acidity (titrable acidity) of clay is expressed as mg of KOH/g of clay on a hot water extract.

4) Moisture content of Earth is vital as activity of clay depends on the evaporation of moisture from earth after its admixture with oil (10 % max free moisture is desirable)

5) The Particle size of Earth affects filtration & oils retention as per type of earth used & determines losses during bleaching process.

6) Operations & maintenance of filters is very important during process.

7) Treatment with Acid Activated Bleaching Earth in post-bleaching step removes traces of Nickel from hydrogenated oils (0.25-0.5% of earth used).

Oil Loss Economics During Bleaching

Spent bentonite fuller earth carries around 30% of oil on dry basis by hot water washing of filter press, the oil content can be brought down to 22% on the average.

Customers’ area now

Europe: UK, Ireland, Netherlands, Czech Republic;

Middle-east: UAE, Saudi Arabia, Iran, Yemen, Egypt, Libya;

Asia: Bangladesh, Thailand, Viet Nam, Philippines, etc.

Packing and Loading Pictures