Product Description

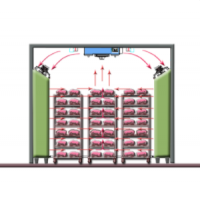

Frozen meat products can achieve to be thawed by controlling the temperature,humidity and working time of the defrosting room.When the ambient humidity reaches about 75% to 95%,a certain humidity increases the temperature conductive medium.It is by air evaporation of frozen meat product itself,water vapor pressure reducing and atmoization naturally reduce the evaporation temperature and air combination.Low temperature and high humidity air go through the cyclic air conveying duct of a special proof variable frequency blower to blow and to formed a uniform airflow on the surface of the product being thawed.By PLC microcomputerautomatc phase controling the defrosting temperature,humidity and time curve to achieve to thaw the products.

The main equipments structure is wall panel,doors of defrosting room,internal structure(wind distribution bracket,plate wind box,water collection sink maderials),electrical control system and refrigeration system.

Technical Standard

1.Low temperature and high humidity air is the main sysem and refrigerating system is as a auxiliary system.The PLC can control the whole system to keep energy-saving and scentific when defrosting.

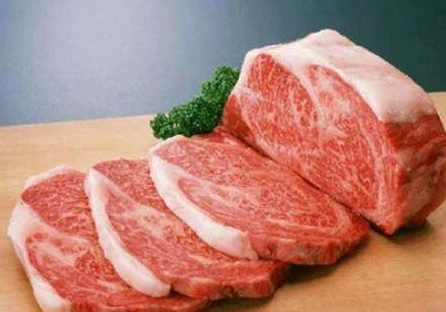

2.After defrosting,the effects of frozen products keep balance,no oxisization and gray line.

3.After defrosting,muscular tissue is full luster and elastic.

4.After defrosting,the lost rate of protein juice is about 1%.

5.After defrosting ,the temperature in the center could be setted at -2±1℃ and can be dustomized.

6.Defrosting type can be setted in several stages and control the process accurately,time controlled at 10-16H according to the different situation.

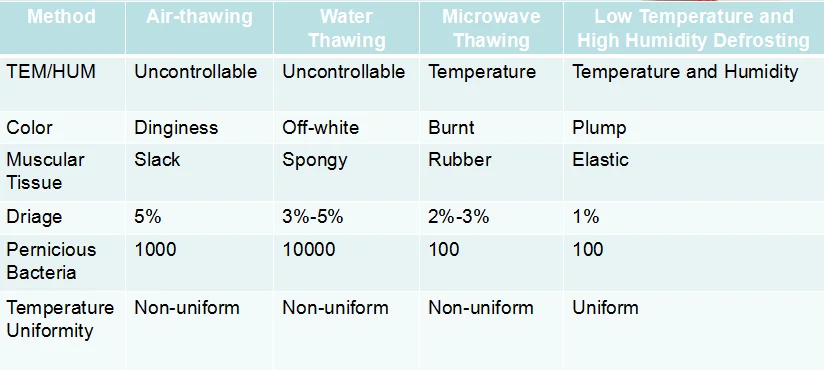

Thawing Advantage

1.Thawing process can be phased control;

2.Maintain the original color and elasticity of the product.

3.Low water loss rate,the minimum protein loss;

4.Product defrosting quickly and evenly,low energy consumption;

5.Controllable low temperature,inhibit microbial growth;

6.High efficiency unit area using;

7.Facilities can be used as cold storage and keeping fresh

Economic Benefit Analysis

The overall economic benefits are reflected in the electricity,water,gas,labor,land occupation,as well as the different product quality.They represent many other aspects of the economic benefits.The following is only a description of weight loss after thawing.Comparison of economic losses caused by loss of weight after defrost(10 tons/day of defrosting of pork).

Company Profile

Our company has passed ISO9001:2008 quality management system certification,ISO14001:2004 environmental system certification and OHSAS18000 occupational health and safety certification.We have successfully obtainer the "One-for-one Technology" R&D Center of Shandong Province,the "innovative specialized new" Innovation Enterprise of Shandong Province,and the "Energy Saving and Refrigeration System Engineering Technology Research Center" in Binzhou,with the Xinjang Academy of Agricultural Sciences,Tianjin University of Commerce,Binzhou college is a strategic partner and a cooperative of industry,academia and research.It is a member of China Refrigeration and Air Conditioning Industry Association,a member of the China Refrigeration institute and a member of Zhongguancun Green Cold Chain Logistics Industry Alliance.

Certification

Our market and customers

Through years of growth and development,the company has matured technology and stable quality of product manufacturing,becoming a professional & efficient management team.As the same time,it has established a good reputation and image in the industry and the market.The company actively develops the market with the business philosophy of "openness,inclusiveness,improvement and innovation".

The products are distributed in dozens of countries and regions such as the United

States,Australia,Russia,Ethiopia,Indonesia,Malaysia,Philippines,Cambodia,Vietnam,Uzbekistan,Ect.

The products are distributed in dozens of countries and regions such as the United

States,Australia,Russia,Ethiopia,Indonesia,Malaysia,Philippines,Cambodia,Vietnam,Uzbekistan,Ect.

Contact us