Product Application

The products are: broad beans, green beans, peanuts and other nuts; Puffed food such as pan and potato chips; River rice strips, cat ears, sand qima, flowers and other products; Meat products such as meat and chicken legs; Yellow croaker, fish and other aquatic products; Bean curd, bean curd, etc. The main application is: fruit: apple, kiwi, wood grape, persimmon, strawberry, grape, peach, pear, etc. Vegetables: tomatoes, sweet potatoes, potatoes, green beans, mushrooms, mushrooms, garlic, carrots, green peppers, squash, Onions, etc. Dried fruits: dates, peanuts, etc. Aquatic products and poultry meat, etc. Simple operation, environmental hygiene and high fuel saving rate are the replacement products of traditional frying machines. Suitable for food processing plants, large and medium-sized hotels, restaurants, various guesthouses, schools, canteen and other catering services.

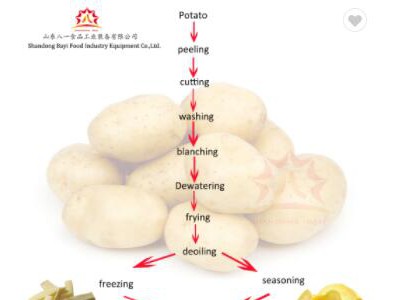

Process flow of potato chip production line

Lifting machine→peeling machine→sorting, conveyer→ Elevator→slicing machine→ Bubble cleaning machine→Blanching machine→ Vibrating screen machine→ De-watering dryer machine →Frying machine →Air cooled drain machine→Conveyor→Mix machine

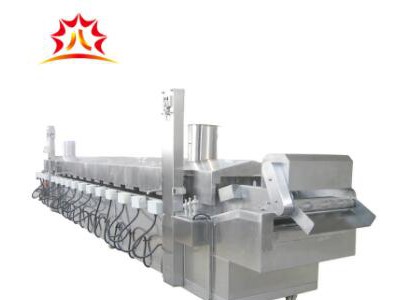

Main Features

The BYFL series large frying pipeline adopts full oil longitudinal scraping slag or side scraping system, frequency conversion speed adjustment. Fried big capacity, increase productivity, frying machine is all stainless steel manufacturing, automatic and manual lifting system, unique product conveying system, discharge system, heating system, oil ring system, exhaust system, electric control system, etc. Suitable for the use of the food in 30 seconds -16 minutes.

According to the customer's energy requirements for the equipment, the heating method is suitable for the users. The machine is suitable for large and medium-sized enterprises. The characteristics of this machine: can save the frying oil for the customers adequately, and the oil and water mixing system can minimize the acid price, peroxide value and carbonization process of frying oil. The appearance, color and taste of the Fried products are superior to those of other frying methods. We have reduced the cost of various frying parts for customers, and maximising profit space for customers.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.