1. Lightweight and convenient:

The structural materials used are high in strength, thin in thickness, and use less steel (usually the total steel for low-rise buildings is within 30Kg/m2, and the steel for multi-storey buildings is within 40Kg/m2).The overall weight of the house is light, only traditional bricks about 1/5 of the mixed structure. The light weight of the structure reduces the transportation and lifting costs, and the base load is also reduced accordingly, which lowers the base cost. It has low requirements for foundation, and is especially suitable for mountainous areas, river beaches, sandy areas, islands and other harsh areas with complex terrain.

2. Safe and durable:

The light steel villa wall, roof structure and inner and outer wall panels form a solid plate rib structure, and the ability to resist horizontal and vertical loads is greatly improved, so the earthquake resistance and wind resistance are better. Tests have proved that it can resist 9° earthquake and 12 hurricane.

The structural parts used are made of high-strength hot-dip aluminum-zinc steel plates, self-tapping screws are used during assembly, and welding technology is not used, which effectively protects the integrity of the aluminum-zinc film and has excellent corrosion resistance. In addition, all structural parts are all enclosed in a water-impermeable composite wall body, which will not corrode, mildew, or fear worms. The service life of the building can reach more than 70 years.

3. Energy saving and environmental protection:

The light steel structure can be 100% recycled and reused, which is of great strategic significance to the steel industry. The combined wall and roofing scheme with excellent performance provides excellent thermal insulation, sound insulation and waterproof performance, and the energy consumption is reduced by 65% compared with the traditional brick-concrete structure.

4.High degree of prefabrication and labor saving:

All building materials of the entire light steel integrated house can be realized in factory mass production and prefabrication, with a high degree of mechanization, there is no wet operation on site, and the real residential industrialization is realized.

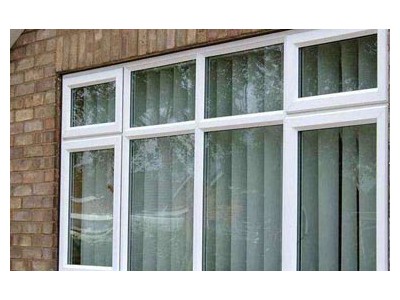

5. High quality and high comfort:

Due to the use of excellent heat insulation, sound insulation and energy-saving structures and materials, the indoor living comfort is greatly improved. The built-in pipeline and the thinning of the wall effectively increase the usable area of the house (increased by more than 10-15% compared to conventional brick-concrete). Coupled with the characteristics of steel knots and structural plasticity, the shape of the house can be complex, diverse and beautiful.

6. Mature technology and perfect matching:

The introduction of advanced technology and years of practical experience have enabled our company to have a complete and mature technology, construction, quality control, and after-sales service system, which has formed a stable and comprehensive supply chain of supporting materials.

7. The basic concept in sound insulation design:

The basic theory of objects blocking air noise is the law of mass.

The basic measurement of sound: decibel (dB), which is the average sound energy flux per unit area per unit time. Representation of sound insulation of objects.

8. Sound insulation measures of light steel structure:

Use sound-absorbing material.

Use soundproof material.

The necessary structural combination measures.

9. Principle of sound transmission:

The source of sound is vibration.

Sound is a wave, and transmission requires a medium.

Transmission, reflection and absorption phenomena occur at the interface of the medium.

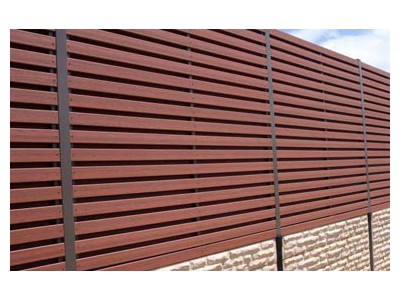

10. Light-acoustic insulation measures for villas in light steel:

The wall is divided into five layers of different materials, and each two different material contact surfaces play a certain role in reflection and absorption.

The thermal insulation and sound insulation material in the middle of the wall is a soft material, which can absorb 80% of the sound wave energy at a frequency of 250 ~ 1000 Hz.

11. Light steel villa knocking sound insulation measures:

The elastic surface treatment reduces the vibration during impact and sees the generation of small acoustic energy.

The elastic cushion treatment makes the surface layer and the structure shock-absorbing and absorbs part of the sound energy.

Floor slab ceiling treatment-When the whole floor slab is hit, air sound is generated.