Milk powder is powder made from fresh milk of mammals such as milk and goat milk as raw materials, after sterilization, cream separation (according to process configuration), concentration and drying. It is suitable for storage and easy to carry. According to Marco Polo’s travel notes, Genghis Khan’s Mongolian cavalry used to carry milk powder. Huiyuan, a Mongolian general at the time, had ingeniously dried it and made milk powder that was easy to carry. As a munitions material, it was very simple and convenient to carry and eat.

Today, milk powder has developed into a wide variety of milk powder with different uses. In simple terms, it can be divided into whole milk powder, skimmed milk powder, semi-skimmed milk powder and various formula milk powder. The best-selling market is a variety of special formula milk powder for infants and young children. The basic production methods are similar, but the equipment configuration and processing accessories are different.

2. System Technology

Generally speaking, the processing of milk powder mainly includes several sections of raw material receiving, pretreatment, concentration, drying and packaging. The actual configuration also includes cleaning in place and energy supply.

(1) Raw material receiving

The milk collected from each dairy farm needs to be filtered, degassed, cooled and then stored in a milk tank. Generally, milk is received once a day, so the storage capacity of the milk tank should be enough for one day's production.

(2) Pretreatment

Pretreatment of fresh milk, including sterilization, cream separation, homogenization and emulsification.

In order to ensure the hygiene of the product, it needs to be sterilized before processing the milk. Sterilization is generally carried out by a pasteurization machine, and ultra-high temperature sterilization can also be used, but the loss of nutritional content of milk caused by ultra-high temperature sterilization is relatively large.

After sterilization, according to the requirements of the product, cream separation of fresh milk. The separated cream can be directly provided to other food processing industries, such as bread or cake production, or it can be further processed into anhydrous cream.

Through the separation, homogenization and emulsification of the cream, the milk can be formulated before further processing to ensure that the produced product has the same quality and has various special nutrients, such as infant milk powder or elderly milk powder.

(3) Concentration

In order to reduce investment costs and save energy, the milk needs to be concentrated before it is dried. According to the characteristics of milk, multi-effect falling film evaporator is generally used for concentration.

Multi-effect falling film evaporator is a new type of concentration equipment. According to different configurations, theoretically one kilogram of steam can evaporate 3-5 kilograms of water. In practice, it is generally lower.

Compared with drying equipment, the evaporator has the advantages of low equipment price, less workshop investment, and energy saving.

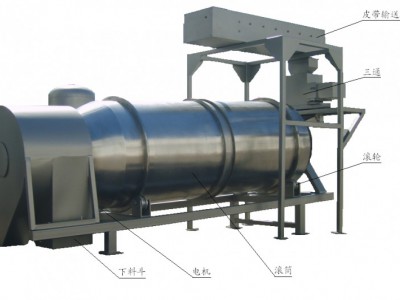

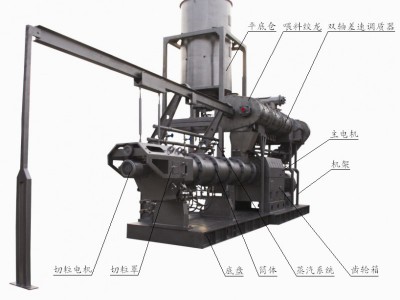

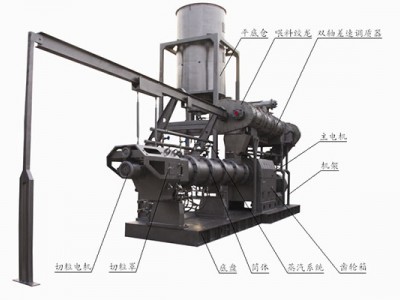

(4) Dry

The concentrated milk needs to be dried in powder form, and spray drying equipment is generally used. The earlier equipment generally uses a centrifugal spray dryer, and its investment cost is relatively low. However, because the solubility of the product is not as good as pressure spray drying, the modern milk powder process has been widely used pressure spray drying.

The drying heating system can be separated from other heating systems in order to increase output and reduce energy consumption.

(5) Cleaning in place

Food equipment needs to be cleaned regularly to ensure the safety and hygiene of products. Manual cleaning is time-consuming and labor-intensive. Our company provides in-situ cleaning equipment, which can save manpower, achieve better cleaning effect, and avoid the bacteria that may be brought in during manual cleaning.

(6) Cleaning

Our company can be equipped with product packaging equipment and energy supply system according to customer requirements, such as the supply of cooling water, chilled water, electricity, steam, compressed air, etc. Customers can also contact local suppliers to provide, our company will provide the necessary cooperation.