1. Introduction to Coffee

It is generally believed that the coffee tree originated in the Kaffa province of Ethiopia in East Africa. According to legend, a shepherd named Kaldi discovered that a goat ate a kind of berry and acted quickly and was energetic. Out of curiosity, he also tried to eat some, and found that these berries refreshed him. This berry, which makes the human body energetic, quickly became well-known in this area and was promoted by monks. The coffee beans then traveled to Yemen and Turkey and then to the European continent via merchants from Venice. With the development of European colonies in the Americas and Asia, in the 18th century, coffee cultivation was introduced into the Americas through the Caribbean and into Asia through Indonesia, and until today it has developed into the world's second largest trading product after oil.

Coffee is mainly divided into three varieties: Arabica (ARABICA), Robusta (ROBUSTA) and Liberica (LIBERICA). Arabica and Robusta are two varieties on the market. Arabica is generally grown at an altitude of 1000 to 1800 meters, while Robusta is generally planted at a relatively low altitude, so Arabica has a relatively low caffeine content. Generally speaking, a fruit of Arabica coffee tree can produce about 0.3-0.4 kg of instant coffee; a fruit of Robusta coffee tree produces more coffee.

The coffee tree is a perennial tropical evergreen shrub that grows only when it is 3 to 5 years old. It has white cluster-like flowers with a shape and smell similar to the tea tree. The flowering period is only a few days. It bears green coffee berries and then turns yellow. , Red, the color gradually becomes darker. The fruit ripening period is generally 6 to 10 months. There are generally two coffee beans in each fruit. The mature coffee beans are like a red cherry, so it is generally called coffee cherry.

After harvesting, the coffee beans are cleaned, peeled, dried, and shelled by dry or wet methods, and sometimes polished to obtain green coffee beans, and then enter the instant coffee production line.

2. Instant coffee equipment

Instant coffee equipment generally includes pretreatment, roasting, extraction, separation and purification, aroma recovery, concentration, drying, agglomeration granulation according to customer requirements and some auxiliary systems according to customer requirements (such as packaging systems and in-situ cleaning systems, etc.) .

Pretreatment

The purchased coffee beans generally need to be sieved, dedusted and then stored for roasting before formal processing. In the separation process, the coffee beans are divided into different grades, while controlling different process parameters during roasting to achieve the best roasting effect. The equipment in this part is relatively simple and the requirements are low. Considering the shipping cost, you can consider making it according to the drawings by the company where you install it, or we can make some small parts for my company, and then make large storage tanks on site. This part of equipment is generally made of carbon steel.

Baking

A small coffee bean contains more than 2000 kinds of substances, only about 700 kinds we can understand so far, and there will be subtle changes between them. The roasting process is to carbonize the active ingredients contained in the coffee, produce coffee fat, and produce good coffee with high quality and consistent style. Traditionally, according to the degree of baking, the baking degree is generally divided into cinnamon, medium baking, urban style, completely urban style, French style and Italian style. In the production of instant coffee, for convenience of description, roasting can be generally divided into light roasting, medium roasting and deep roasting. In order to maintain the best coffee flavor, for the best coffee beans, generally use medium roasting. The aroma produced during the roasting process can be filled into the coffee packaging through the pipeline to preserve the best coffee flavor.

extraction

After roasting, some unique aroma components in coffee will withstand lower temperatures. The traditional extraction process makes a large amount of coffee aroma lose, and the extracted coffee aroma is not enough. There are many processes to add some food additives to the extracted solution to enhance the taste of coffee. Such a process is that coffee loses its most important charm as a natural drink that most attracts end consumers.

The extraction process used by our company retains the natural aroma of coffee to the greatest extent and is separated and stored by a flash separator. The extraction part generally includes six to eight extraction tanks. The design of each extraction tank is required to withstand a pressure of 25 kg, which is convenient for slag discharge, and is controlled by a reasonable process circulation device. Our company's special design can increase the solid content of the extracted coffee solution from traditional 12-13%, according to customer requirements and specific configuration, to 18-22%, thereby reducing the investment cost of downstream equipment and reducing the system Energy consumption.

Separation and purification

During the processing of coffee beans, it inevitably contains a part of ash. It is also easy to mix some fibrous substances in the coffee solution. In order to improve the quality of the product and ensure that the instant coffee produced after the end consumer dissolves, there is no visible content, we generally recommend that after extraction, equipped with a separation device. Generally, the coffee extract solution has a very low content, so it can be equipped with a disc separator with a relatively high degree of separation and purification. The high-speed rotating disc separator can ensure that most of the insolubles in the solution are separated.

concentrate

There are two main purposes of concentration, one is to increase the concentration of the extract before the drying process (spray drying or vacuum freeze drying), thereby reducing the investment cost of the drying section; one is to reduce the water content of the extract, thereby reducing the energy Consume.

In some processes, the concentrated coffee extract can be sold directly to make some canned drinks, such as canned liquid coffee, or further processed into other end consumer products, such as coffee candy, coffee biscuits, or coffee snacks.

In order to improve the utilization rate of energy and save operating costs, according to the size of the production line and considering the investment cost, two-, three-, four- or five-effect falling film evaporators with hot-pressure pumps can be configured. Generally, the concentrated coffee has a solid content of 35-55%. There are also membrane filtration and freeze concentration processes on the market, but they are generally only suitable for special requirements and are not recommended.

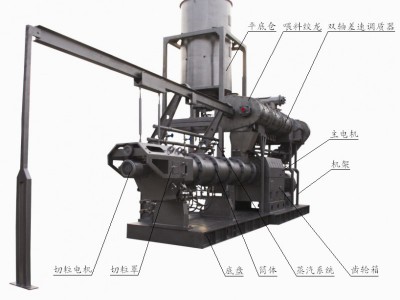

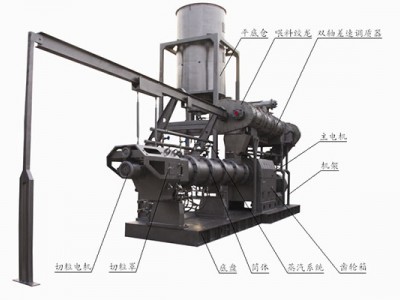

dry

Coffee drying is generally divided into freeze-drying and spray-drying: freeze-drying includes foam pre-cooling, quick-freezing tunnel, crushing and granulation, freeze dryer and crushed powder return to several parts. Freeze drying can retain the flavor and color of coffee to the greatest extent. The final product's color, flavor, density and solubility and other quality indicators are more in line with market demand, so the product's sales price is relatively high. However, the investment cost of freeze drying is large, the operating cost is high and the proportion of powder returned is very high, which limits the development of freeze drying. The most spray-dried products on the market now. After special treatment, the flavor and bulk density of the spray-dried product can achieve very good results.

After years of research and development by our company's technical staff, we can provide special designs and processes in terms of product size, bulk density and fluidity. In particular, traditional coffee spray drying generally combines an external fluidized bed for cooling and drying. The design of our company can achieve the final moisture content and product packaging temperature required by customers through the built-in fluidized bed. The size of spray-dried products is generally 100-350 microns according to the size of the specifications and the configuration of the equipment.

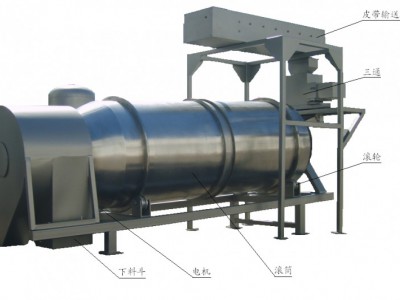

Agglomeration granulation

In order to adapt to some markets that require large particle products and require no dust, our company also provides agglomeration granulation equipment to process the small particle products produced by spray drying into large particle products. According to the different needs of different customers, the general agglomeration granulation process can control the average particle size of the product to 1000-2000 microns.

Automation control

The control of the equipment can be of many different levels, such as button control, semi-automatic control and automatic control.

The most commonly used is the semi-automatic control system, which has a relatively low cost, requires fewer operators, and related parameters can also be recorded and controlled.

For more advanced automation, you can use the SCADA system to detect the operating status and parameters of the control system, and to collect and retain data records in order to effectively track each batch of products. Regardless of semi-automation or automation, we use standardized components and modules to facilitate customer maintenance. For international customers, we will ensure that we can provide the best service for relevant component modules through consultation with customers.

Our control system can do: turn on and off the system's startup and shutdown; manage and detect the system's automatic startup, shutdown and cleaning procedures; can set different formula parameters to suit different products and meet different needs in different markets ; Record the real-time situation of each process project, and record and back up as needed, while retaining the trend curve

Cleaning in place

The cleaning of food equipment is a time-consuming and labor-intensive work that takes up production time. Our company can provide different levels of in-situ cleaning systems for customers to choose according to their different requirements.