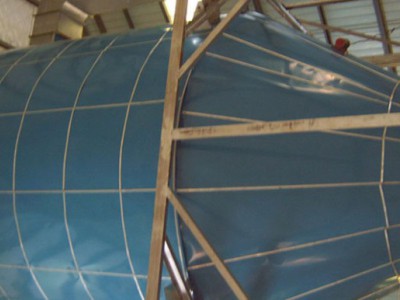

The traditional Chinese medicine extract spray dryer is generally centrifugal and uses a closed form. All materials, products and air contact parts are made of high-quality stainless steel, equipped with a three-stage purification device, and the filtered air reaches the 10,000-level requirement. The barrel is equipped with a cold wall device, so that the temperature is less than 80 degrees Celsius, and the material does not appear to be scorched and deteriorated even if it stays on the wall, which greatly improves the powder collection rate (up to 98-99%), and does not cause drug mixing and Wall sticking.

According to different product characteristics and customer requirements, air sweeping or wall scraping can be configured at the same time to increase productivity.

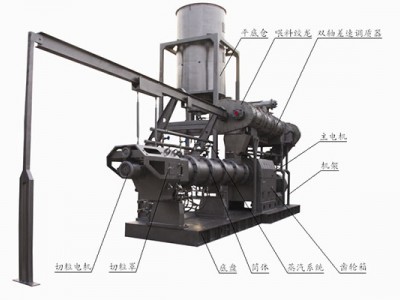

° The special dryer for Chinese medicine extract spray is a special equipment that absorbs the early technology at home and abroad. It is mainly suitable for drying products with low melting point and high sugar content, and has the characteristics of non-stick wall and not easy to absorb moisture. The device is based on the product's Characteristics to determine the spray drying process conditions, high degree of automation, easy operation, in line with'GMP, requirements.

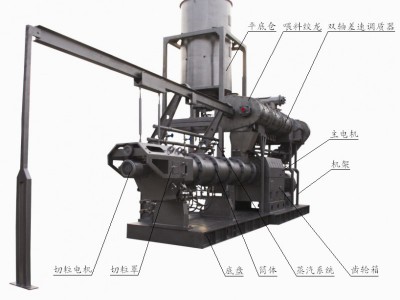

based on the characteristics of products and equipment, our company has newly developed a pressure type Chinese medicine spray dryer, which can avoid wall sticking, improve product quality, simplify processes, and increase product particle size and solubility.

Second, the basic principle:

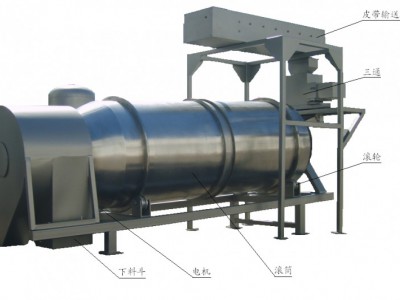

The traditional Chinese medicine extract high-speed centrifugal spray device is the application of centrifugal spray drying technology in the drying of specific materials, and it also uses a high-speed centrifugal atomizer to disperse the materials into a mist form and fully contact with the hot air to complete the instant drying to form a powder Drying device for finished products.

LPG high-speed spray dryer in the following conditions in the drying of traditional Chinese medicine extract:

1. The material is easy to stick to the wall and the powder collection rate is low;

2. The material stays on the wall for a long time, causing coking and deterioration of the material;

3. It is difficult to clean and does not meet GMP requirements;

4. Low output: LPG-150 spray dryer, its actual output can only handle 50-60kg/h feed liquid.

In view of the above situation, a few years ago, our company designed the Chinese medicine extract dryer to solve the above problems according to the material properties and process requirements of the Chinese medicine extract. The material after drying the product has good color, no deterioration, and greatly improved product quality. Compared with the LPG high-speed centrifugal spray dryer, the traditional Chinese medicine extract has the following characteristics:

1. Three-stage air purification and filtration are adopted to make the air intake meet the requirements of 300,000 grades;

2. The cold wall device is adopted to make the inner wall temperature reach 80°C, and the material stays on the wall without coking;

3. The entire volume is 3.5 times that of the original LPG standard centrifugal spray;

4. Adopt quick opening flushing device, which is suitable for production requirements of many varieties;

5. The dust removal adopts wet dust removal, so that the dust does not go out, which meets the environmental protection requirements;

6. The air sweep device is adopted, and its effect is more satisfactory;

7. Provide 2 sets of atomizers and adopt frequency conversion to adjust speed;

8. PLC control is adopted, and the screen display of the program control system;

9. Can be equipped with flushing device;

10. It can be equipped with dry air tightly conveyed. Recently, our company newly developed pressure type Chinese medicine extract spray dryer, in addition to the above characteristics, also has the following characteristics:

11. Large particle size and good fluidity

12. Avoid sticking to the wall and improve product quality

13. Good product quality and good solubility

14. The equipment configuration is simple and easier to operate

15. The equipment structure is simple and the maintenance cost is relatively low

The main disadvantage of the pressure spray Chinese medicine extract dryer is that the investment cost is relatively high, mainly because the drying tower is relatively high, so the required plant is relatively high, and the construction cost increases accordingly. It is mainly suitable for products with high product requirements and high added value.