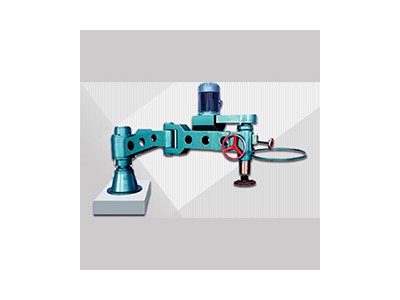

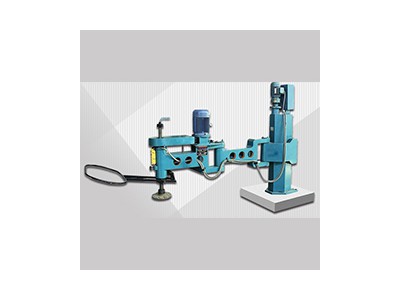

The single arm combined stone sawing machine in the combination saw based ,it has changed the traditional vertical slide guide by optimizing the modified by four column hydraulic precision orientation.It has high guiding precision,small vibration,these advantages make it popular.Due to the rigid,with small clearance and lubrication advantages make the single arm combined stone sawing machine sheet thickness error is small,smooth surface of high.What’s more ,the service life of the cutter head saw blade is improved,and the labor saving is reduced.Four column hydraulic combination saw is an ideal device for a sheet processing.

Main technique parameter of the single arm stone sawing machine

|

model |

XDZ8 |

XDZ12 |

XDZ14 |

XDZ18 |

XDZ22 |

|

Blade diameter |

Φ1650mm(2200mm) |

||||

|

Number of saw blades |

8(1650×4+980×4) |

12 |

14 |

18 |

22 |

|

Lift stroke |

1000mm(1300mm) |

||||

|

Main motor power |

37kw/45kw |

45kw/55kw |

55kw/65kw |

65kw/75kw |

75kw/90kw |

|

Water consumption |

16m³/h |

20m³/h |

26m³/h |

34m³/h |

40m³/h |

|

Total weight |

7500kg |

8000kg |

8500kg |

9000kg |

11500kg |

Product feature and application of the single arm stone sawing machine

These series machines have reasonable structure, steady working conditions, and can be equipped with multi discs.These series single arm combined stone sawing machine can combine 6-20 saw blades one time according to use diameter 1600mm,1800mm,2200mm,2600mm.The lead screw of the trolley is equipped with protective device and clearance adjusting device,this setting mode improves the service life of the screw and the slice precision greatly.The lifting and lowering of the single arm stone sawing machine adopts the gear reducer to drive the lifting screw to use the saw blade lifting.the maintenance is convenient,the failure rate is low ,and the latest our column hydraulic lifting is also available.

·full sealed four-cylinderguider rail is used for rising and falling which makes the whole structure more stable.Reduces wear and keeps the machine in the best working state for long time.

·Traditional screw lift is replaced by hydraulic lift,which reduces mechanical wear, maintenance costs and time and lowers production costs.

·Using oil cylinder for towing trolley solves all problems about traditional reducer towing which leads to stable and reliable operation and long service life without regular maintenance.

·Electric automatic slice separating improves the precision of products,reduces labor intensity and improves production efficiency.

FAQ

Q. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q. How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q: When the manufacturers shipped the product?

A: delivery term within 15 days after get the down payment.