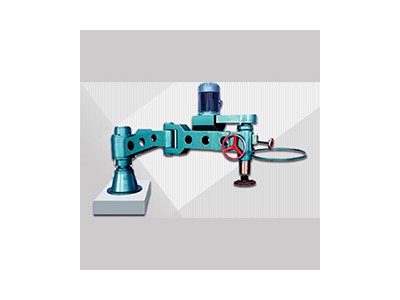

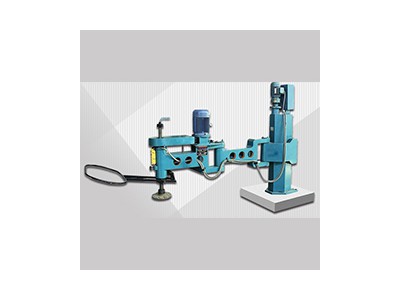

1 . Product Introduction of the Bridge Type Strips Stone Cutting Machine

Strips stone is one of the most widely used building material products. Bridge type strips stone cutting machine is the necessary processing equipment for this kind of products.

The spindle box is mounted on the upper and lower drag boards, which move up and down through the screw rod, and the upper and lower drag boards are mounted on the left and right drag boards, which move left and right through the screw rod. The cutting saw blade is mounted on the spindle box, and the blade can move up, down, left and right.Four V-wheels under the worktable are driven on the oil-immersed guide rail of the seat by gear teeth row to realize the straight-line reciprocating motion of the worktable.

The PLC programmable control system of the machine automatically traces the curved (straight) line model through the optical fiber probe, and uses the diamond saw blade to automatically imitate and cut the curved (straight) line shaped stone products. Up and down and left and right cutters are controlled by program automatic control, and the worktable is controlled by frequency converter speed regulation. It can be adjusted according to the stone material, and can also realize the processing of arc lines. It has high automation, high cutting accuracy, double knife design, high cutting efficiency and good stability. Simple operation, especially suitable for lines, arc lines, Roman columns. Machining of special-shaped stone such as large circular arc plate.

Bridge type strips stone cutting machine automatically traces the model of curved (straight) line through optical fiber probe, and uses diamond circular saw blade to automatically imitate and cut into curved (straight) line shaped stone products;The working table of the bridge type strips stone cutting machine adopts frequency conversion speed regulation, which can be adjusted according to the stone material, such as selecting and matching rotary working table, and can also realize the processing of circular arc lines. The whole machine of the bridge type strips stone cutting machine adopts micro-computer control system with high automation and high cutting precision. The bridge type strips stone cutting machine adopts double-knife design, which has high cutting efficiency, good stability and operation.It is simple and especially suitable for processing special-shaped stones such as lines, arc lines, Roman columns and large arc plates.

2 . Product Parameter(Specification) of the Bridge Type Strips Stone Cutting Machine

|

model |

DTS100-120 |

|

The number of saw blade |

6-8 piece |

|

Saw blade diameter |

Φ900mm-Φ1200mm |

|

Total power |

32.85kw-40.75kw |

|

Overall dimensions |

7000(L)×5000(W)×4000(H)mm |

3 . Product Feature And Application of the Bridge Type Strips Stone Cutting Machine

1.The cutting speed is fast, the running precision is high, and the operation is simple and convenient.

2.Easy installation and maintenance. Low failure rate and long service life.

3.It has a high market share and is now exported to more than 90 countries and regions with good value preservation.

4.Suitable for special-shaped lines.

5.The crossbeam is provided with a protective cover.

6.Oil-immersed track with protective cover.

7.Stronger and more stable, large-scale worktable, more suitable for large-scale stone processing, lifting column, the same use of oil-immersed sealed rail worktable, double-knife design, more efficient and stable.

8.High degree of automation, high cutting accuracy, the use of double-knife design, cutting efficiency, good stability. Simple operation, especially suitable for lines, arc lines, Roman columns. Machining of special-shaped stone such as large circular arc plate.

4 . Production Details of the Bridge Type Strips Stone Cutting Machine

5 . Product Qualification of the Bridge Type Strips Stone Cutting Machine

6 . Deliver,Shipping And Serving of the Bridge Type Strips Stone Cutting Machine

7 . FAQ

Q:How can you make your order process faster?

A:Since we usually only distribute and deliver the goods after the payment arrives, prompt remittance after the order is placed can ensure that your order is processed faster.

Q:This machine is generally suitable for what industries

A:Wooden door and furniture decoration industry, wooden process processing industry.

Q:Does this machine have a run-in period?

A:Engraving machine belongs to professional products, its structure is complex. So the new machine must have a run-in period.It will take at least one month (200 hours or more) for the machine to reach a good condition

8.Latest News

The key of WEDM is its accuracy, because the machine tool is the "working machine". only the high-precision machine tool can produce high-precision machinery and further promote the refinement of products. As a kind of machine tool, high precision is also the goal of the industry. Although the technical ability is strong, the WEDM machine tool produced by the disconnection from the market and the constraints of planned economy has not only high failure rate, but also limited performance (only cutting 50mm thick, efficiency is about 30mm?/min). However, the WEDM machine tool is a unique machine tool in China. Compared with the WEDM machine tool abroad, its precision is lower, but its performance is limited. Manufacturing and use costs have absolute advantages and are very suitable for those developing countries, precisely because of the demand of this potential market.

From the point of view of social environment, China has not been implementing market economy for a long time, and some small WEDM machine tool factories are still in the accumulation stage of original capital. These factories often do not have the whole manufacturing capacity, but can only be assembled production. The quality control of the whole production process is not at all possible, and R&D and innovation are even more impossible. This kind of manufacturer is very rare in the eastern part of China. Many, coupled with the immaturity of China's market economy laws, these non-productive enterprises will continue to survive. From the current situation, the state's attitude towards this is to eliminate it naturally through market competition. The core of the development of functional compounding of WEDM machine tools, especially mid-line WEDM machine tools, is to complete turning, milling, drilling, tapping, winching and reaming on a machine tool, so as to improve the efficiency and accuracy of the machine tool and the flexibility of production.

With the development of intelligence, the future WEDM machine tools will also usher in the era of intelligence, machine tool operators at the grass-roots level are facing a severe test. It is necessary for some enterprises to use machines instead of people to do mechanical work. Specialized robots can make greater efficiency in the shortest time, and the future cutting machine tools will enter the era of intelligence.