Production

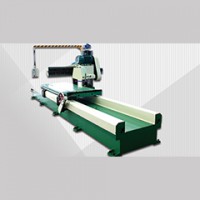

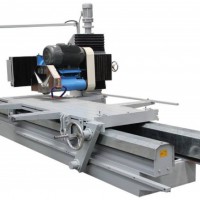

Hand operated stone edge trimming machine is mainly used for cutting stone and other materials. It is mainly composed of frame, fixed table and cutting tool.The structure of the hand trimming machine utility model is simple and the operation is convenient. In the process of processing, the stone can be lifted up through the lifting platform to complete trimming. When the lifting platform falls, the stone can be transmitted through the conducting shaft roller, thus greatly improving the processing efficiency, and reducing the labor intensity of workers, and according to the needs. The worktable is rotated, thus greatly improving the scope of application, good stability, good applicability and strong practicability.

Main technique parameter

|

Saw blade diameter |

Φ400/600mm |

Table size |

2000×840mm |

|

Main motor power |

11kw/15kw |

Space installation dimensions |

7000×2600×2200mm |

|

Horizontalmoving distance of saw blade |

1200mm |

Table travel |

3000mm |

|

Power of lifting speed reducer |

0.75kw |

Pump motor power |

0.75kw |

|

Saw blade lift stroke |

400/300mm |

Total power |

12.25kw |

|

Spindle support rotation angle |

0°-90° |

The quality of (approximately) |

2700kg |

Advantage of hand trimming machine

1. Hand operated stone edge trimming machine add the length of the beam,so that the cutting width increased to 1200mm.This length increase the lift motor to achieve the electric lift.

2. Hand trimming machine increase the blade shroud,the power of the main motor.This can use diameter 400mm to 600mm saw blade to achieve cutting below 160mm stone plate.

3. The hand-operated stone trimmer increases the pulleys of different diameters, and the pulleys can be exchanged to adapt to the rotational speed required by saw blades of different diameters.

4. The worktable of XSQ60 hand trimmer is connected with the main engine on the basis of the original oil-immersed guide rail, so that the machine does not need a specific foundation to install, only needs to select a flat concrete structure ground to be installed, and then can be used with slight adjustment. It is more convenient to relocate and install.

Specific implementation methods

The hand-operated trimmer includes a machine base, a worktable set on the machine base, a vertical support rod set on the machine base and a cutting tool support frame set on the vertical support rod, a cutting tool base set on the cutting tool support frame, a concave cavity with a top opening, and a conducting shaft roller set on the top of the worktable. The workbench is provided with a conducting motor connected with the conducting shaft roll, a lifting platform is arranged in the concave cavity, a vertical guide slide bar is arranged in the bottom wall center of the concave cavity, a slide hole matching the vertical guide slide bar is arranged in the bottom center of the lifting platform, an eccentric wheel is arranged between the lifting platform and the bottom wall of the concave cavity, and an eccentric wheel is arranged between the lifting platform and the bottom wall of the concave cavity. The side wall is provided with a hand-rocking action bar connected with the concave cavity, and the hand-rocking action bar is fixed with the middle part of the eccentric wheel. The lifting platform performs lifting action on the vertical guide slide bar under the action of the eccentric wheel. A rotating shaft bar is also provided between the workbench and the machine base, and a rotating strip groove hole is arranged on the side wall of the machine base and a rotating strip groove is arranged on the rotating strip groove. The hole is provided with a hand rocker rotating rod fixed with a rotating shaft rod. The hand-rocked rotary bar is used to adjust the rotation of the rotary shaft bar.

The side wall of the concave cavity is provided with a vertical guide chute, the side wall of the lifting platform is provided with a guide slider matched with the vertical guide chute, and the top wall and the bottom wall of the vertical guide chute are provided with a buffer pressure spring.

The top surface of the lifting platform is provided with anti-slip bumps. The weight of stone and anti-slip protrusion are used to locate the stone. The working table is provided with a speed regulating knob connected with the conduction motor.

The utility model has the advantages of simple structure and convenient operation. In the process of processing, the stone can be lifted up through the lifting platform to complete trimming. When the lifting platform drops, the stone can be transmitted through the conducting shaft roller, thus greatly improving the processing efficiency, reducing the labor intensity of the workers, and can work according to the needs. The table is rotated, thus greatly improving the scope of application, good stability in use, good applicability and strong practicability.

Obviously, the above-mentioned embodiment of the utility model is only an example to clearly illustrate the utility model, but not a limitation on the implementation mode of the utility model. For ordinary technicians in their fields, other forms of changes or changes can be made on the basis of the above description. There is no need and no way to exhaust all the implementation methods here. The obvious changes or changes derived from the essential spirit of the utility model still belong to the protection scope of the utility model.