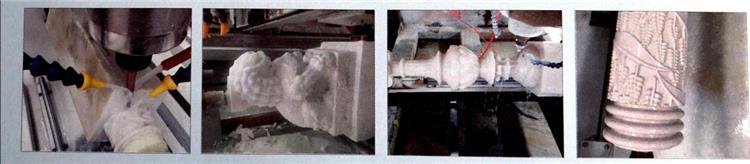

This model can not only process the plane relief, but also can process the cylinder and other surrounding three-dimensional graphics, one machine dual-use, maximize the utilization rate of equipment, especially suitable for processing tombstone, column board, interior decoration and other industries.

General situation of Double heads stone engraving machine

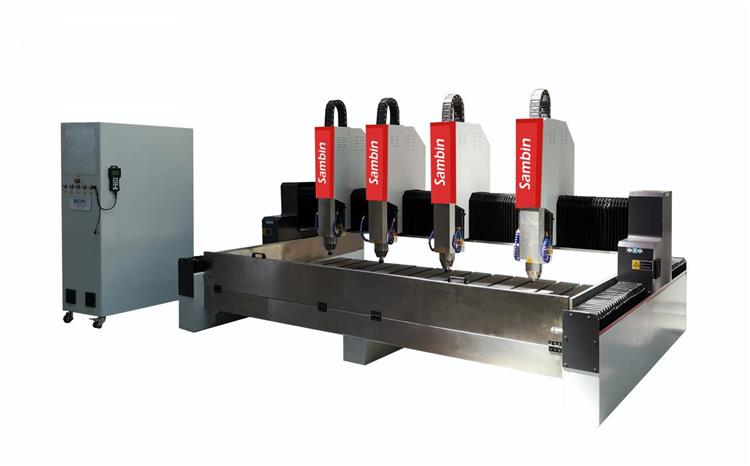

The machine has high precision, fast speed, wide range of application. Its four shafts are all driven by high - power servo motor. This machine can work steadily for a long time.This is a multi-functional four-axis four-linkage stone carving machine, processing size, wide range of application. Its four shafts are all driven by high power servo motor with high machining precision and fast machining speed. It can work steadily for a long time and has a very high processing efficiency. Processing diameter, processing length, the number of head can be customized according to customer requirements. May carve the Roman column, the column head, the column cap, the Buddha statue, the stone lion, the circle dragon column and so on.

Product features and applications

1. Four-axis and four-linkage control system can complete engraving, hollowing and pluralistic special-shaped three-dimensional engraving of all planar plates.

2. Multiple working heads are processed simultaneously with rough carving and fine carving. The processing efficiency is several times higher than that of ordinary machine carving.

3. imported original guide rail, lead screw, air-cooled spindle with zero failure rate, legitimate weihong operating system, and large torque driving motor constitute a fast CNC machining tool to minimize labor costs and truly realize the work to the machine.

4. The machine is suitable for carving, hollowing and cutting wood doors, furniture, bed head, sofa, chair back and other flat surfaces; Suitable for stair column, furniture leg, sofa leg, tea table leg, chair leg, such as three-dimensional workpiece fine carving processing.

Product ion details

1. A six-table mobile three-dimensional engraving machine has a total of 6 spindles, capable of 6 three-dimensional samples at the same time. This machine adopts imported high-precision square guide rail, double rows and four rows of sliding blocks, and the screw adopts Taiwan precision grinding ball screw. It has high precision, accurate cutting, fully ensure the speed and accuracy of the machine tool. This machine has high bearing capacity, smooth operation, high precision and long service life.

2. The bed and gantry of the machine are welded seamlessly with steel structure, and the machine is treated with high temperature and aging treatment. The machine has strong steeliness and no deformation. The pulley and other parts are made of industrial castings with stable performance, non-deformation and long service life. Z axis wall plate adopts casting parts, professional anti-resonance design.

3. The spindle frequency conversion system adopts beisde high performance frequency converter, with stable performance, fast speed increase, stepless adjustable and strong resistance to radio interference.

4. The system is compatible with Artcam, Type3, Coreldraw, wen tai and other CAD and CAM design and production software. It can control the completion of multi-layer 3D processing, and can be fast and smooth 3D processing.

5. The installation technology of z-axis back triangular structure and the layout of guide rail triangular structure of this three-dimensional engraving machine greatly reduce the resonance generated by z-axis, improve the service life of guide rail slider and improve the carving precision.

6. The cable of the whole machine can reciprocate up to 8 million times with YC special numerical control machine tool and high flexible shielding machine tool.

7. This machine is equipped with American industrial aviation plug and soft metal cable sheath. Therefore, avoid cable damage caused by pressure and collision.

Product parameters

|

Product series |

1825-2D-2X |

2025-2D-2X |

|

Plane machining range |

1800*2500 |

2000*2500 |

|

Feed height |

450 |

450 |

|

Three-dimensional processing range |

The diameter of 400, The length of the 2000 |

The diameter of 400, The length of the 2000 |

|

Spindle power |

5.5KW |

5.5KW |

|

Maximum processing speed |

10m/min |

10m/min |

|

Drive system |

Step/servo |

Step/servo |

|

Control system |

Four axis four linkage system |

Four axis four linkage system |

FAQ:

What kind of bed does the machine use?

The machine adopts t-type weighted bed to make it durable and stable.

What is the maximum machinable diamete?r

This factory produces the three-dimensional stone material carving machine maximum may process the diameter 0.60 meters.