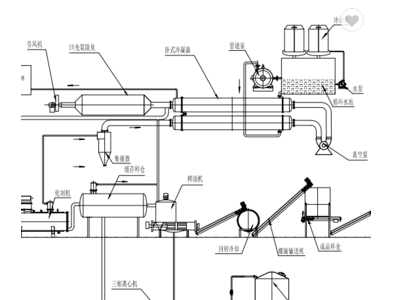

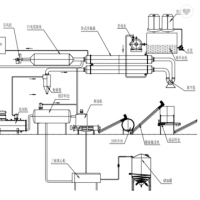

Performance characteristics: The unit is designed for small fish meal processing plants with less investment and quick results. Cooking, pressing and drying are integrated. Using heat conducting oil as carrier and electromagnetic heating method, the steam boiler is replaced. The power of electric heating is 60 kW and the working temperature of heat conducting oil is 180 C. Total power consumption: 70.7 kw/h (60 kW + equipment running 10.7 kw) processing capacity: 2 tons of fish raw materials / 8 hours, suitable for aquatic products processing enterprises, aquatic waste disposal office and small fish meal factories with unstable raw materials. Equipment parameters: Stainless steel 304 is used for external insulation of electric heating cooking machine_510 *3000, thickness 0.7mm; Q235B carbon steel is used for inner and outer barrel of equipment; transmission power: 1.5kw (excitation speed regulation; dryer specification 820 *3500 power 4kw single-axis press 245 *1200 power 2 kw), and 1.5KW power of conveying cage_200 *4000 to deal with small miscellaneous fish by steaming. Cooking will cook the material, and then the cooked material will be degreased by pressing to achieve degreasing effect. The cake will be dried by steam dryer. Under the action of stirring teeth, the material will be fully dried and the finished product will be obtained.