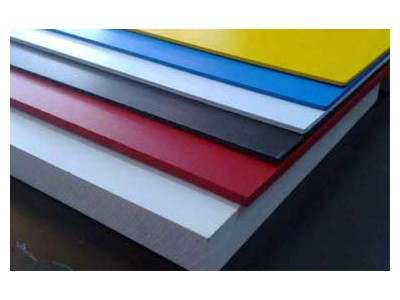

PVC hard board is a board made of PVC as raw material. PVC hard board is a widely used product in industry, especially in the chemical anti-corrosion industry. PVC is a resin resistant to acid, alkali and salt. Because of its good chemical properties and relatively low price, it is widely used in various industries such as chemical industry, building materials, light industry and machinery.

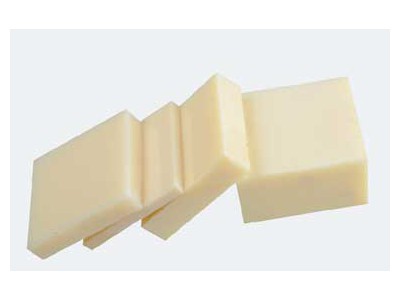

Polyvinyl chloride, abbreviated as PVC in English, is a polymer formed by the polymerization of vinyl chloride monomer in peroxides, azo compounds and other initiators; or under the action of light and heat according to the free radical polymerization reaction mechanism. Vinyl chloride homopolymer and vinyl chloride copolymer are collectively referred to as vinyl chloride resin.

The hard PVC board is usually made of rolled PVC sheet and heated and pressed. PVC hard board pressing is divided into 3 heating stages, 1 adjustment stage, and 1 cooling stage.

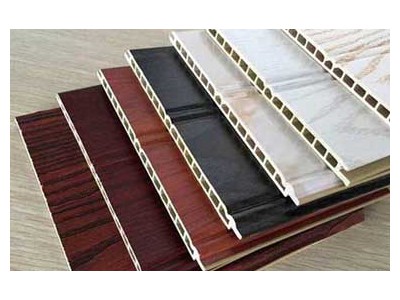

PVC hard boards are usually made by PVC board manufacturers using rolled PVC sheets to be heated and pressed. According to needs, this kind of PVC rigid board can be flexibly made into various thicknesses. As PVC is a thermally unstable resin, it will decompose to remove HCl and form a polyene structure. If processed at high temperature for a long time, it will seriously affect product performance. However, PVC is also a poor heat conductor and slow heat transfer. To prepare products with good performance, the heating time is difficult to control. If the heating time is not enough, the inside of the board is easy to layer; if the heating time is too long, it will not only reduce the production efficiency, What's more serious is that PVC will accelerate decomposition at high temperature for a long time, which will affect the performance of the product.