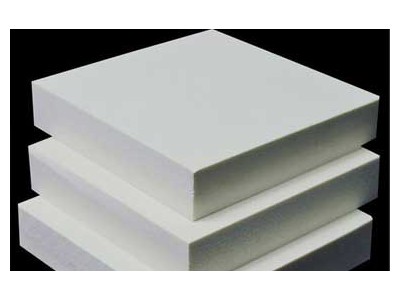

PVC Andy board is also called PVC expansion sheet and Chevron board. Take polyvinyl chloride as the main raw material, add foaming agent, flame retardant and anti-aging agent, and adopt special equipment for extrusion molding. Common colors are white and black.

PVC Andy board is comparable to wood, and it can be sawn, planed, nailed, glued, and has special functions such as no deformation, no cracking, no painting (various colors), and low-foaming boards can be welded , Ink printing and can also be machined by sawing, drilling, milling and other methods.

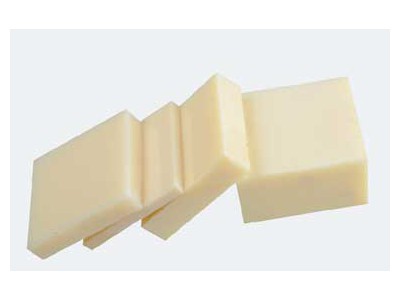

There are two common production methods for PVC board (Andy board): one is skinning and foaming, with a hard skin on the surface, smooth and flat; the other is free foaming, without skinning on the surface, and the surface is fine. Concave and convex (pitted surface).

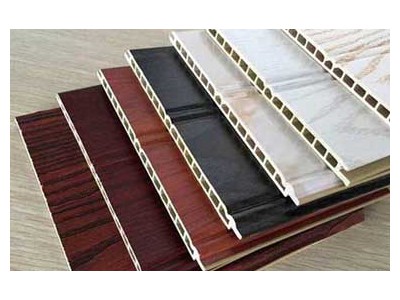

PVC Andy boards are widely used in construction, vehicle and ship manufacturing, furniture, decoration, decoration, advertising production, exhibition signs, city appearance and environmental protection, tourism and other industries. The advertising characters are made by an engraving machine or by hand, and the thickness is generally 0.3-2 cm. Common colors are white and black.

The PVC Andy board produced by PVC board manufacturers is comparable to wood, and can be sawn, planed, nailed, and glued, and has special functions such as no deformation, no cracking, and no need to paint (with multiple colors); and low The foamed sheet can be welded, printed with ink and can also be machined by sawing, drilling, milling and other methods.