10#Precision steel pipe

10# precision steel tube is a high-precision steel tube material processed by cold drawing or hot rolling.

advantage:

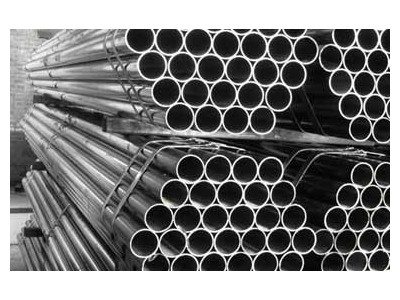

10# precision steel pipe has no oxide layer on the inner and outer walls, withstands high pressure without leakage, high precision, high smoothness, cold bending without deformation, flaring, flattening and no cracks, so it is mainly used to produce pneumatic or hydraulic components, such as cylinders Or the cylinder, which can be a seamless tube or a welded tube.

use:

10# precision steel pipes are widely used in automobiles, motorcycles, electric vehicles, petrochemicals, electric power, ships, aerospace, bearings, pneumatic components, seamless steel tubes for medium and low pressure boilers, etc., and can also be applied to steel sleeves, bearings, hydraulics, machinery Processing and other fields.

Production Process:

Tube billet-inspection-peeling-inspection-heating-piercing-pickling passivation-grinding-lubrication and air drying-cold rolling-degreasing-cutting-inspection-marking- -Product packaging.

Features:

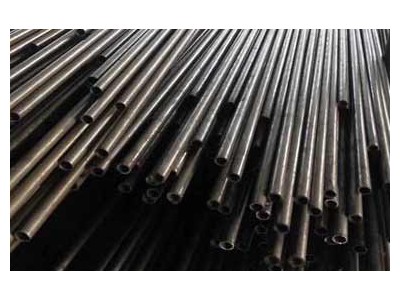

1. The outer diameter is smaller;

2. High precision and small batch production;

3. The cold-drawn product has high precision and good surface quality;

4. The horizontal area of steel pipe is more complicated;

5. The performance of steel pipe is superior, and the metal is denser.