(1) "8" shaped safety hook. The opening and closing mechanism is a spring tongue automatic reset type, and the lock arm is equipped with a self-locking bolt composed of a safety pin, a compression spring and a wrench. When opening the hook, lift the wrench with your fingers to disengage the safety pin, and press the lock arm down to open it. If it is released, the lock arm will automatically reset under the elastic force of the return spring, while the self-locking bolt closes the hook opening through the outward elastic force of the opening and closing mechanism. At the same time, the spring hook is sold directly by the factory. The compression spring will tighten the safety pin and lock the lock. The arms are locked.

(2) The "D"-shaped safety hook is composed of a hook body and a locking arm. The opening and closing mechanism is a spring tongue automatic reset type. The locking arm part has two safety structure designs: torsion self-locking and threaded hand lock, self-locking structure lock The arm is equipped with a rotating compression spring, the lock arm sleeve can be automatically reset and locked, the hand lock structure has threads on the lock arm, and the rotating lock arm sleeve can open and lock the safety hook.

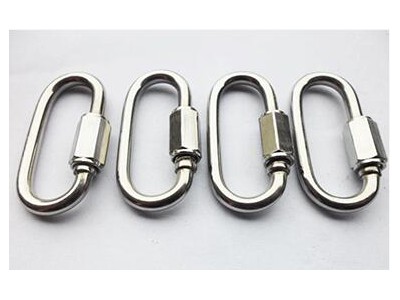

Spring hook material

The material of the safety hook is usually divided into stainless steel, alloy steel or aluminum alloy. The steel safety hook is hard and heavy, and is suitable for connecting anchor points or contacting sharp metal equipment, such as connecting safety harnesses and descenders. The breaking load of aluminum alloy shackles is not inferior to that of steel products, and aluminum safety hooks are relatively light in weight, suitable for connecting various equipment of personal protective equipment and carrying multiple spares. But aluminum alloy is less resistant to cutting, so avoid hooking with other sharp metals when using it.

Snap hook inspection and maintenance

The shape of the safety hook should be checked frequently. If there is any deformation or cut marks, it should be discarded and no longer used. If sand or iron filings enter the lock teeth, it should be washed immediately. After use, the alloy steel safety hook should be maintained with anti-rust agent and stored in a special container. If the safety hook accidentally falls from a height (above 2m) onto a hard ground, even if its appearance is not damaged, its internal alloy composition may have been severely damaged and should be discarded and avoided from being used again.