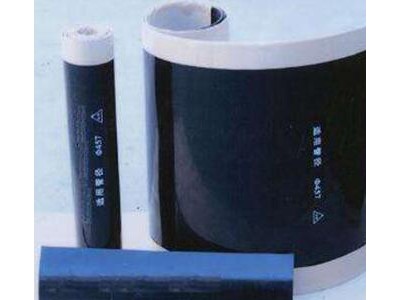

Shrink wrap for pipelines is a kind of 3LPE structure heat shrink tape. It employs irradiation HLPE or LDPE as the backing material, high performance hot melt adhesive layer, and antiseize parting film as the cover.

Features

Shrink wrap for pipelines offers the hardness, mechanical protection and resistance to moisture absorption required on critical higher temperature, and often pipelines.

High-up temperature epoxy on the steel apply resistance to corrosion and to cathodic disbandment while allowing relatively low installation temperatures.

Parameter

|

Property |

Test Temp. |

Unit |

Requirement |

Test result |

Test method |

|

Thickness |

— |

mm |

Not less than 0.85 × nominal value |

- |

Annex B |

|

Holiday detection at 5 kV/mm + 5 kV |

— |

— |

no holiday |

no holiday |

Annex C |

|

Impact resistance (holiday detection at 5 kV/mm 5 kV after recovery) |

20℃ |

J/mm |

Not less than 5 |

6 |

Annex D |

|

Indentation resistance (holiday detection at 5 kV/mm 5 kV after recovery) |

60℃ |

N/mm2 |

10.0 |

10.0 |

Annex E |

|

— |

mm |

Not less than 0.6 |

1.20 |

||

|

Cathodic disbondment at 30 days |

23℃ |

mm |

Not more than 5.0 |

4.8 |

Annex G |

|

60℃ |

mm |

Not more than 10 |

8.9 |

||

|

Peel strength at 10 mm/minto pipe surface primed with epoxy and to plant coating |

23℃ |

N/mm |

Not less than 4.0 |

12.3 |

Annex I |

|

60℃ |

N/mm |

Not less than 0.20 |

0.5 |

||

|

Peel strength at 10 mm/min |

23℃ |

N/mm |

Not less than 0.75 |

0.85 |

Annex I and Annex H |

|

Lap shear strength at 10 mm/min |

23℃ |

N/mm2 |

Not less than 1.0 |

3.5 |

Annex J |

|

60℃ |

N/mm2 |

Not less than 0.07 |

0.18 |

||

|

Thermal ageing resistance (aged at Tmax + 20 °C) |

23℃ |

E100/E70 |

Not less than 0.75 |

0.94 |

Annex M |

|

23℃ |

P100/P70 |

Not less than 0.75 |

0.92 |

Detail

Application

With high performance anti-corrosion coating - two components primer.CYG heat shrink tapes offers high performance protection as the factory made coating for the oil, gas and water pipelines, fittings, elbows,bends and other irregular articles.

Our Factory

Our Service

We draws upon its powerful Technology team, big producing capacity, well-known purchasing ability and close relationship with manufactures to offer full line products with exceptional quality, and bring productivity improvements to our clients.

FAQ

Q:What is your lead time?

A:Generally 3 days for in stock cables and 7-10 days for customized cables.

Q:What is your payment method?

A:We usually receive payment by T/T, L/C, Western Union or Paypal.

Q:Do you accept OEM and ODM?

A:We accept OEM order for our customers, and we also have a strong research development

team to design specialized wires and cables for ODM.

Q:Do you have Certification of Products.

A:We have ROHS Certificate.

Q:Can I get sample before order?

A:Sample is welcome and it is free if we have stock.

Packing And Shipping