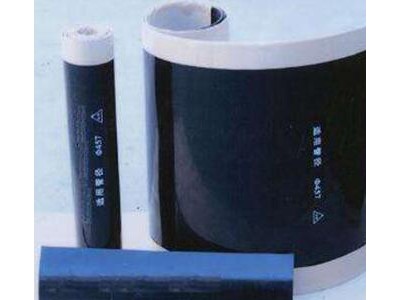

The oil pipelines anti corrosive tape produced by our company is a new type of anti-corrosion cold-wrap tape developed on the basis of traditional polyethylene anti-corrosion tape. The base material is a high- and low-density synthetic polyethylene base material, and the adhesive layer is a high-viscosity thermoplastic modified butyl self-adhesive anticorrosive adhesive, supplemented by a layer of anti-adhesive release film.

Features

① Strong viscosity and self-fusion, waterproof, gas penetration, and good sealing.

② High electrical insulation, excellent aging resistance and strong resistance to ultraviolet radiation.

③ It has the ability to resist soil stress damage and strong impact resistance.

Parameter

|

Item&Standard |

T-150 |

T-165 |

T-175 |

|

Total thickness(ASTM D 1000) |

0.510 mm |

0.635 mm |

0.762 mm |

|

Backing thickness(ASTM D 1000) |

0.310 mm |

0.335 mm |

0.390 mm |

|

Adhesive thickness(ASTM D 1000) |

0.200 mm |

0.300 mm |

0.372 mm |

|

Elongation at Break(ASTM D 1000) |

( 400% |

||

|

Tensile Strength(ASTM D 1000) |

55 N/cm |

60 N/cm |

63 N/cm |

|

Yield Strength(ASTM D 1000) |

40 N/cm |

45 N/cm |

50 N/cm |

|

Peel Adhesion to Primed Steel Pipe(ASTM D 1000) |

22 N/cm |

28 N/cm |

30 N/cm |

|

Dielectric Strength(ASTM D 1000/D 149) |

35 KV |

42 KV |

45 KV |

|

Cathodic Disbandment (ASTM G8) |

0.24 in radius 6.4 mm |

||

|

Volume Resistivity(ASTM D 257) |

2.5 x 1012 ohm.m |

||

|

Water Vapor Transmission Rate (ASTM F1249) |

( 0.1gm/M2/24h |

||

|

Water Absorption Rate(ASTM D 570) |

< 0.10% |

||

|

Recommended Application Temperature |

-5 to +60℃ |

||

|

Max Serve Temperature |

-40 to + 85℃ |

||

|

Color |

Black |

||

|

Available Roll Size (width x length) |

2" to 32" X 50’ to 800’ |

||

How To Use?

1. Pipe surface processing

Thoroughly clean the surface of the pipe by removing all foreign material.Completely remove any sharp projections from the area of the weld.Remove all rust and/or other impurities using a steel brush.

2. Apply primer

Before application, shake or mix primer thoroughly.

Because it is highly volatile, make sure it is securely sealed after use.

Because it contains inflammable solvents, use caution when working near any open flames.

To obtain best results, apply primer in a temperature range of 0°C~25°C and for storage a temperature of -20°C~35°C is best.

Proper volume of primer is 100g per 1m².

When primer is applied and PE anti-corrosive tape is used, it is recommended to apply the tape within a short time after the primer is completely dry.

Application

Can be widely used in oil, natural gas, chemical industry, water supply and drainage in urban construction, oil and gas, steel pipelines and steel ground storage tanks for external anticorrosion and repair projects. It is the latest non-pollution and non-hazardous environmental protection anticorrosive material.

Our Factory

Serves for Oil, Gas and Water Transmission pipeline market、Oil and Gas distribution and utility markets,New pipeline construction markets,Rehabilitation and Reconditioning market,Offshore Industry,Refinery and Petrochemical Plant Industry.

FAQ

Q1:What is the payment terms?

A:T/T , L/C at sight,

Q2:How long is the production cycle?

A:Usually 5-10 days after payment, but it will cost more time when a large order made.

Q3:What is your MOQ?

A:Usually 500 kilograms.

Q5:What certificates do you have for your products?

A:We have some patents and several certificates such as ISO9001, ISO14001,SGS, CNPC, DVGW for our products.

Q6:Is the sample free?

A:Usually sample is free,customer take care of express charge.

But it should paid if asking for large quantity samples.

Q7:What qualifications does your company have?

A:The anti-corrosion series products produced by our company have been widely used in large-scale underground chemical pipe networks such as SINOPEC, CNPC and CNOOC, as well as gas, oil and water pipelines of major oilfields.

Q8:How can I visit your factory?

A:You are welcome to visit our factory, just contact us in advance.Our factory address is Shandong Province ,China.

Packing And Shipping